Quick reference

23

(S

OFT

03.1

X

)

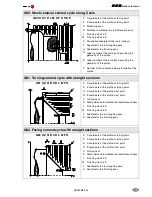

G160. Drilling / tapping canned cycle on the face of the part

Drilling:

G160 X Z I B Q A J D K H C S R N

Tapping:

G160 X Z I B0 Q A J D S R N

D

Safety distance along the Z axis and indicates how

far from the starting point the tool will approach the

part.

K

Dwell, in hundredths of a second, at the bottom of

the hole before starting the withdrawal.

H

Withdrawal distance in rapid (G00) after each

drilling along the Z axis.

C

Defines the approach distance along Z from the

previous drilling step to start the next drilling step (in

G00).

X

X coordinate where the cycle is to be executed.

Z

Z coordinate where the cycle is to be executed.

S

Live tool turning speed and direction.

I

Depth referred to the starting point.

B

Type of operation to be executed:

R

In the drilling cycle:

• B=0: Tapping.

• B>0: Drilling.

• Factor that reduces the drilling peck (step) "B".

In the tapping cycle:

Q

Angular position for the spindle to execute the cycle.

• Type of threading to be executed.

N

Number of the spindle for the live tool.

A

Angular step between two consecutive operations.

J

Number of holes to be drilled or tapped.

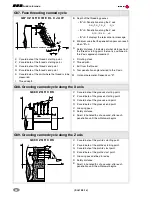

G161. Drilling / tapping canned cycle on the side of the part

Drilling

G161 X Z I B Q A J D K H C S R N

Tapping

G161 X Z I B0 Q A J D S R N

J

Number of holes to be drilled or tapped.

D

Safety distance along the X axis and indicates how

far from the starting point the tool will approach the

part.

K

Dwell, in hundredths of a second, at the bottom of

the hole before starting the withdrawal.

H

Withdrawal distance in rapid (G00) after each

drilling along the X axis.

C

Defines the approach distance along X from the

previous drilling step to start the next drilling step (in

G00).

X

X coordinate where the cycle is to be executed.

Z

Z coordinate where the cycle is to be executed.

S

Live tool turning speed and direction.

I

Depth referred to the starting point.

B

Type of operation to be executed:

R

In the drilling cycle:

• B=0: Tapping.

• B>0: Drilling.

• Factor that reduces the drilling peck (step) "B".

In the tapping cycle:

Q

Angular position for the spindle to execute the cycle.

• Type of threading to be executed.

N

Number of the spindle for the live tool.

A

Angular step between two consecutive operations.

Summary of Contents for CNC 8070

Page 1: ...Quick reference SOFT 03 1X REF 0706 CNC 8070...

Page 44: ......