®

17

Obstacle Avoidance

PHASE II

—

System Installation Detail Cont’d

Connect Supply & Return Lines

5” EPDM hose couplers are used to make a semi flexi-

ble connection from a SunSaver

®

bank to Schedule 40,

2” PVC piping. Below is the best order to follow for con-

necting the supply and return lines:

1. Check that all supply lines are connected to the lowest

end of their collector row and that the upper ends feed

to a common high point in the system. (as in

Figure

5

).

2.

Connect 5” couplers on upper and lower inserts of

all collector corners for supply and return plumb-

ing. Be sure to install hose clamps as depicted in

Figure 9.

3. Route supply line to the bottom header of each row

4. Route the return line to the upper header of each

row.

5. If there are straight pipe runs in the plumbing ex-

ceeding 15ft without an offset, there must be either

a plumbing expansion kit installed or an industry

standard method to accommodate for any expan-

sion and contraction (see

Plumbing Layout

and

Ap-

pendix C

for details).

6. Both supply and return line plumbing must be

mounted so that it is allowed to move an equivalent

of 1/2” for every collector between it and the Fix

Mounted collector in the bank. If there are multiple

collectors, it may be advisable to install an Expan-

sion joint immediately in the plumbing so that

when the bank moves with temperature, the plumb-

ing will be able to absorb the movement immediate-

ly. Refer to

Plumbing Layout

and

Appendix C.

CAUTION: Overtightening Hose Clamps will deform

connectors and accelerate compression set in de-

formed EPDM hose and will lead to leaking. Torque

all hose clamps to 35-42 in-lbs.

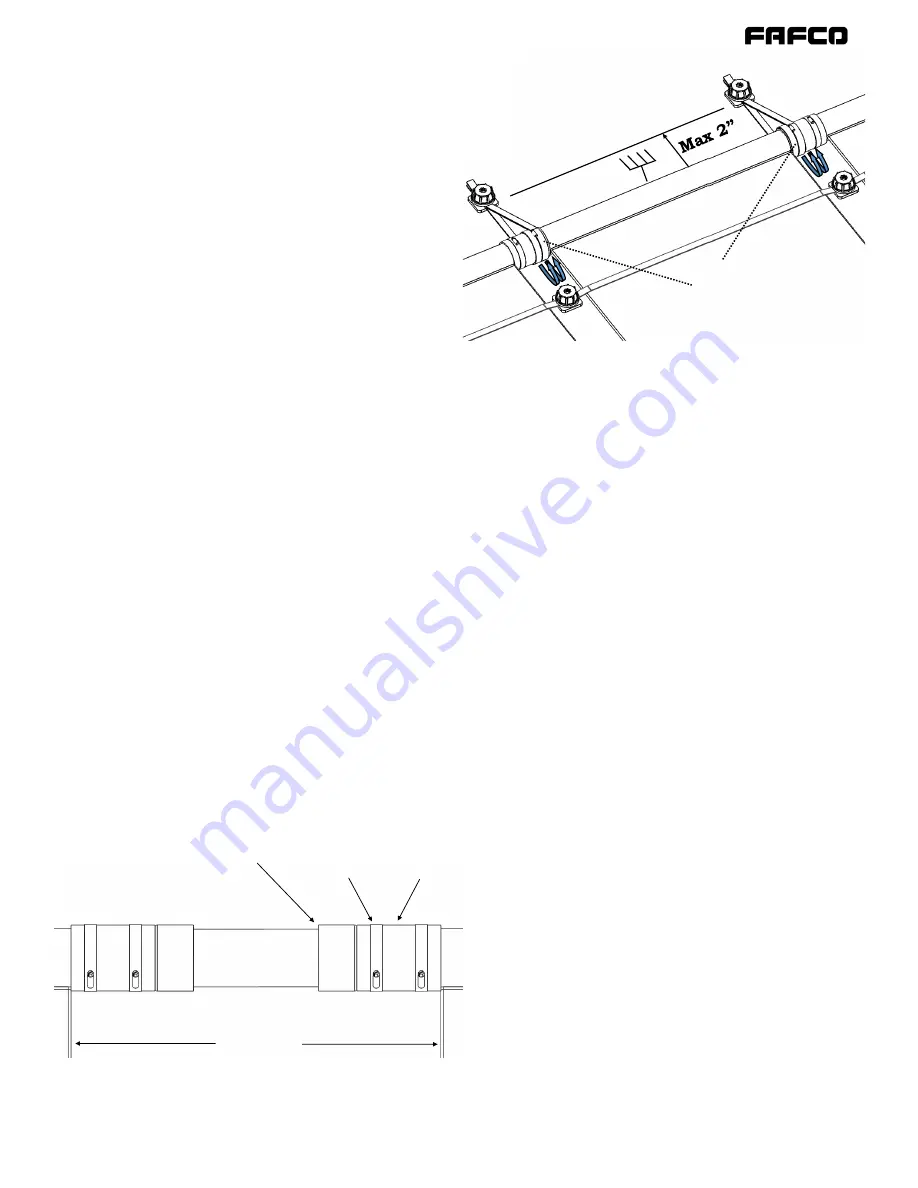

Figure 10 | Adding Space to a Row

In order to accommodate for obstacles in a row, collectors may need

to be spaced out by adapting the couplers to PVC.

Collectors

PVC Pipe

Pipe

Adapter

Hose

Clamp

Coupler

Since the collectors are made of a polymer that sees

large temperature swings, there can be a lot of natural

movement in an array as well as all plumbing. If sim-

ple practices are not adhered to, this natural move-

ment can cause damage to solar collectors, plumbing

and roof penetrations.

As seen in

Phase I

,

Plumbing Layout

and

Appendix C,

SunSaver

®

banks move both laterally and longitudi-

nally along the roof. It’s often best to mount the mid-

point of the bank so that the movement is divided

evenly to both sides of the bank. This can be done by

double wrapping a header strap around the fixed col-

lector on both upper headers and installing the Caps/

Bases up to 2” away from the header (see

Figure 11

).

Use a means of fix-mounting this collector which best

fits the practices of installation company. The plumb-

ing end of the bank will move simply from the move-

ment of the bank which will then translate to the

plumbing. Since there can be movement translated to

the plumbing, it’s crucial to plumb the banks so that

this movement can either be absorbed in the coupler

or absorbed in the plumbing. To accommodate for

movement in the banks, all plumbing must be coupled

to the bank with a 5” coupler and if there is a long run

of plumbing going directly to the bank, accommoda-

tions for thermal expansion must be utilized. Refer to

the

Figures 16 and 20

in

Appendix C

.

Collectors may need to be spaced out to allow for mid-

bank obstacles or changes in roof shape. In most cas-

es, the banks will need to have additional spacing

added so that the bank can be plumbed around the

Figure 11|The Fix-Mounted Collector

On the

Fix-Mounted Collector

, the upper headers should be double

wrapped on both sides to keep the Collector as an inflection point of

bank movement. A means of limiting bank movement should be used

which best fits the practices of the installation company.

Double

Wrap

(Fixed Points)