11

햲

햳

햴

햵

햶

햸

햷

햹

햺

These instructions apply to the following models:

844 R Reversible

The 844 R Reversible FAAC automated system for sliding gates is

an electro-mechanical operator which transmits movement to

the sliding leaf via a rack and pinion appropriately coupled to

the gate.

The reversible system enables the gate to be moved manually

when the motor is not operating. Consequently, an electric lock

must be installed to ensure locking during closure.

The gearmotor is equipped with an adjustable mechanical

clutch which makes it possible to adjust the thrust force exerted

on the gate.

A handy manual release facility makes it possible to move the

gate in the event of mechanical problems with the gearmotor.

The electronic control unit can be housed inside the operator

(462DF) together with the installation kit, or in a separate

enclosure (578D or 462DF) - see chapter 5.

The 844 Reversible automated system was designed and built

for controlling vehicle access. Do not use for any other purpose.

1.

DESCRIPTION AND TECHNICAL SPECIFICATIONS

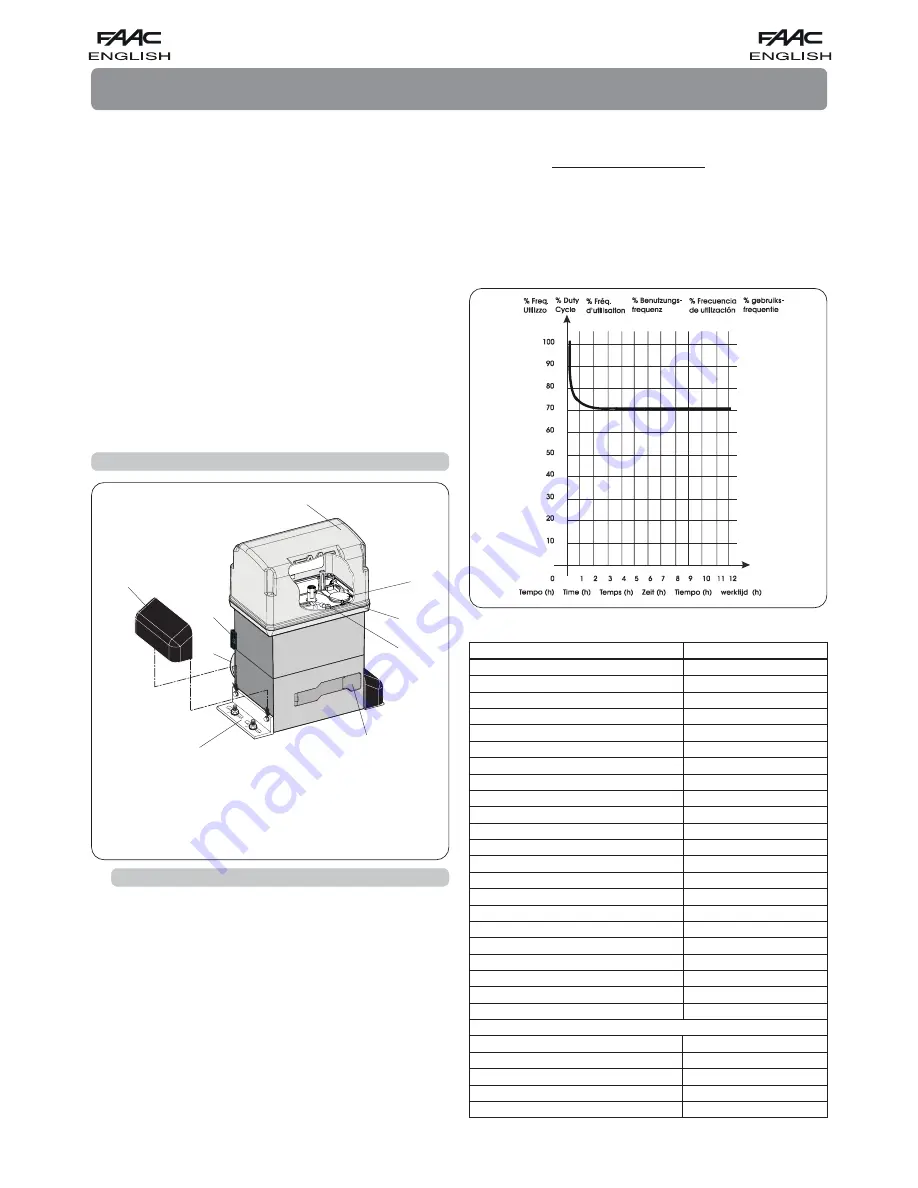

Fig. 1

햲

Securing corners

햳

Pinion

햴

Limit sensor

햵

Operator cover

햶

Clutch adjustment

screw

햷

Oil filling plug

햸

Operator earthing

햹

Lever-operated release device

햺

Protective side-panels

1.1.

MAXIMUM USE CURVE

The curve makes it possible to establish maximum work time (T)

according to use frequency (F).

E.g.: The 844R Rev. gearmotor can operate non-stop at a use

frequency of 70%.

To ensure efficiency operation, operate in the work range under

the curve.

Important

: The curve is obtained at a temperature of 24°C.

Exposure to the direct sun rays can reduce use frequency down

to 50%.

Calculation of use frequency

The percentage of effective work time (o closing)

compared to total time of cycle (o c pause

times).

where:

Ta = opening time

Tc = closing time

T p = pause time

Ti

= time interval between one complete cycle and another

Use frequency graph

844 R Reversible AUTOMATED SYSTEM

Tab. 1

TECHNICAL SPECIFICATIONS OF GEARMOTOR 844R REV.

MODEL

844 R Reversible

Power supply (Vac +6% -10% 50-60Hz)

Absorbed power (W)

Reduction ratio

Type of pinion

Rack

Max. thrust (daN)

Max. torque (Nm)

Winding thermal protection (°C)

Use frequency

Oil quantity (l)

Type of oil

Operating ambient temperature [°C]

Weight of gearmotor (Kg)

Protection class

Gate max. weight (Kg)

Gate speed (m/min)

Gate max. length (m) (time-out)

Clutch

Protective treatment

Available units

Limit-switch

Gearmotor overall dimensions LxHxD (mm)

Electric motor technical specifications

RPM

Power (W)

Absorbed current (A)

Thrust capacitor (µF)

Power supply (Vac +6% -10% 50-60Hz)

230

550

1 : 10

Z12

module 4 pitch 12.566

68

18

140

70 % (see graph)

1.8

FAAC XD 220

-20 to +55

15

IP 44

1000

11.6

48

twin-disk in oil bath

cataphoresis

578 D - 462 DF

M L S

see Fig. 2

750

550

2.5

25

230

Calculation formula:

Ta + Tc

%F =

X 100

Ta + Tc + Tp + Ti