44

PREVENTATIVE MAINTENANCE:

Unit Serial #: _____________________ No. of Humidi

fi

ers: ______________________________________________

Model #: _________________________________ Voltage: _______ V/ ___ Ph.

Steam Output: _______ lb./hr.

Customer/Job: ___________________________ Address: ______________________________________________

PREVENTATIVE MAINTENANCE:

RECOMMENDED MONTHLY PREVENTATIVE

MAINTENANCE FOR HUMIDIFIERS

Service contractor or maintenance agent - be prepared to:

1. Investigate and observe.

2. Recognize

issues.

3. Determine

procedures.

4. Implement

solutions.

5. Inform

customers.

Preventative maintenance is not intended to replace

quality manufacturing and assembly from the company of

origin. Products get older, wear and tear occurs, personnel

changes and simple attention to detail sometimes become

lax. Basic preventative maintenance for humidifiers should

be required follow-up for continued proper operation of

products. Preventative maintenance is a means to prevent future

costly failures. The following are recommended preventative

maintenance procedures for humidifiers on a monthly basis:

PLEASE FOLLOW ALL REQUIRED SAFETY

PROCEDURES BEFORE WORKING ON HUMIDIFIER

UNITS.

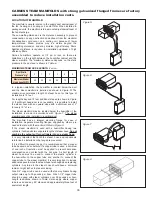

1. Visually inspect steam hose(s) and condensate hose(s)

for proper routing and installation from humidifier

unit. Prevent sags, dips, or kinks in hoses. Eliminate

horizontal runs. Make sure there is an adequate

slope up for the steam hose and slope down for the

condensate return. Correct as necessary. Recommend no

hose lengths longer than 10 feet. Refer to earlier pages

of this IOM.

2. Visually inspect steam hose and condensate

attachment to dispersion pipe or short absorption

manifold. Recommend periodic removal of dispersion

systems for inspection (restricted dispersion holes,

damage, plumb mounting, and clamping tightness).

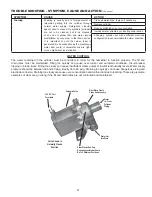

3. Humidifier unit - inspect internal hoses for sediment build

up or degradation. Clean or replace as necessary. Also,

check tightness of hose clamps. Tighten as necessary.

4. Inspect fill valve strainer. Industrial/commercial unit fill

valve strainer is located at the connection point of the

water inlet hose to valve. Strainer is located inside the

valve at the threads. Pop out using a non-sharp tool and

inspect. Clean or replace as necessary.

5. Visually check operation of the drain solenoid valve,

smooth operation and 100% seal when normally closed. If

necessary, remove solenoid valve, disassemble and clean

or replace as necessary.

6. Visually check the cylinder for extreme amounts of

residue on the inside surface. Very high levels of water or

the unit unable to provide full capacity may be an indication

that the cylinder is at the end of its life. Do not attempt to

clean out with chemicals; do not stick screwdrivers or other

objects into cylinder to clean out sediment. These cylinders

are made to be replaced at end of life cycle. Life cycle of

a cylinder is often determined by the condition of the water

used in the unit, especially hardness, % of max output, or

run time (24/7, 8 hr./day, etc.). Refer to this IOM or main

humidifier catalog for more information.

7. Visually and manually check all wires and connections

inside the unit. Include inspecting the wire connections to

the top of the cylinder. If a red 90° connector is used, be

sure to check the inside of the connector for a set screw.

This screw needs to be checked for tightness. Make sure

control wires at the J16, J17 and J18 terminal connections,

bottom of the circuit board, are tight.

8. Monthly - remove drain air gap and check for any

sediment buildup that may block any free flow of water.

These check points for the “H” series humidifier are basic, but

significantly covers the entire unit.

Keeping a preventative maintenance record would be

recommended to show maintenance performed and any

observations made during inspection.