9

3

TRANSPORTATION AND

INSTALLATION

3.1. Handling the Unpacked Machine

Make sure the machine is safely loaded and

balanced when moving it with a forklift, failing to

do so may cause personal injury or damage to the

machine.

3.2. After Unpacking the Machine

Put the machine in a dry and sheltered place to

prevent damage to the electrical and mechanical

components.

Apply

appropriate

lubricant

(machine oil or grease) on the slide ways and

non-painted areas to prevent rust.

3.3. Environmental Conditions

Mains voltage and frequency complying

with the machine motor characteristics.

Environment temperature from -10° C to

50° C

Relative humidity %10 to %90

3.4. Machine Placement and Position

The followings should be considered when

positioning the machine:

The floor:

The machine should be placed on a

lecelled concrete floor.

Working Area:

Sufficient space should be

allocated around the machine for comfortably

loading and unloading work stock and for easy

access during maintenance and repair. When

necessary, all doors and access panels should be

opened without interference.

Lighting:

The machine and its surroundings

should be well lit for operator’s safety and for a

convenient operation and maintenance.

4

PREPARATION BEFORE

OPERATION

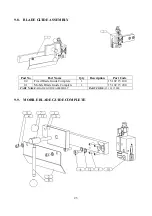

4.1. Cleaning

Unpainted and uncoated machine surfaces were

coated with a rust inhibitor prior to shipment. -

The rust inhibitor should be cleaned with an

appropriate solvent. To prevent rust on unpainted

surfaces, a light coat of machine oil can be

applied.

4.2. Lubricating

Lubricate all the sliding parts before starting.

4.3. Coolant

The machine is shipped with the coolant reservoir

empty. Fill the reservoir with coolant until it is

full. A sight gauge is mounted on the machine

base to check coolant level.

Caution:

Do not run the coolant pump without

coolant in the reservoir. Otherwise, the coolant

pump will be damaged.

4.4. Electrical Power Connection

1.

Electrical connection must be done by a

qualified electrician, in conformance with the

required electrical standards of your area.

2.

Turn off the main circuit breaker of the area in

which the machine will be located.

3.

Machine's power cord should be connected to

an appropriate power source; make sure the voltage

rate matches the one required for the machine.

4.

It is important that the shipping brace should

be removed from the saw before taking any further

step.

Note

: If the ‘emergency stop button’ is

depressed, it must be released for the machine to

run.

Summary of Contents for PGM 280

Page 1: ...PGM 280 OPERATION MANUAL ...

Page 27: ...28 10 CONTROL CIRCUIT DIAGRAM ...

Page 28: ...29 11 POWER CIRCUIT DIAGRAM ...