11

5-

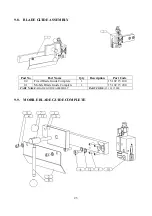

Loosen the bolts on the carbide blade

guides. Lower the blade from bandsaw

guides.

6-

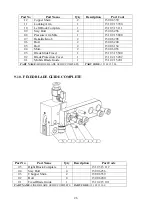

Lower the chip brush away from the blade

by loosening the chip brush locking lever.

Caution:

Wear heavy protective work gloves and

safety glasses when handling blades to avoid

injury.

7-

Carefully remove the blade from the saw.

8-

Uncoil the new blade and insert the blade

around the band wheels.

Warning:

New blades are generally shipped in a

coiled from. This puts them under tension and can

suddenly be uncoiled. Take extreme caution to

revent injury when uncoiling the new blade. Make

sure you wear safety gloves and glasses. Locate

back of edge the blade into the carbide inserts

(pressure pads) and guide bearings so the teeth

point in downward direction.

9-

Press the back edge of the blade firmly

against the back-up of the carbide guides

10-

Turn on the main switch of the machine.

11-

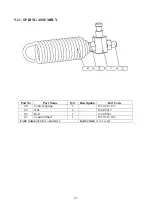

Turn the hand-wheel to right (to

tensioning position) to apply a

light

pressure

.

12-

Press the back edge of the blade firmly

against the flange of each band wheel.

13-

Turn the hand-wheel to right (tensioning

position) to exert sufficient tension on the

saw blade.

14-

Turn off the main switch of the machine.

15-

Turn the bolts clockwise to tighten the

carbide pressure pads against the blade.

Tighten the carbide guides by hand only.

Note:

Do not over-tighten the carbide pressure

guides.

16-

Adjust the position of the chip brush so

that the bristles reach fully into the gullet

of the blade without extending beyond.

Then lock the chip brush in place.

Important:

Improper positioning of the chip

brush will result in excessive blade or chip

brush wear.

17-

Make sure that you close and secure the

band wheel covers and blade guards at the

end of this process.

Summary of Contents for PGM 280

Page 1: ...PGM 280 OPERATION MANUAL ...

Page 27: ...28 10 CONTROL CIRCUIT DIAGRAM ...

Page 28: ...29 11 POWER CIRCUIT DIAGRAM ...