Design and function

TIG cold wire welding

42

099-000115-EW501

17.06.2015

5.9.2

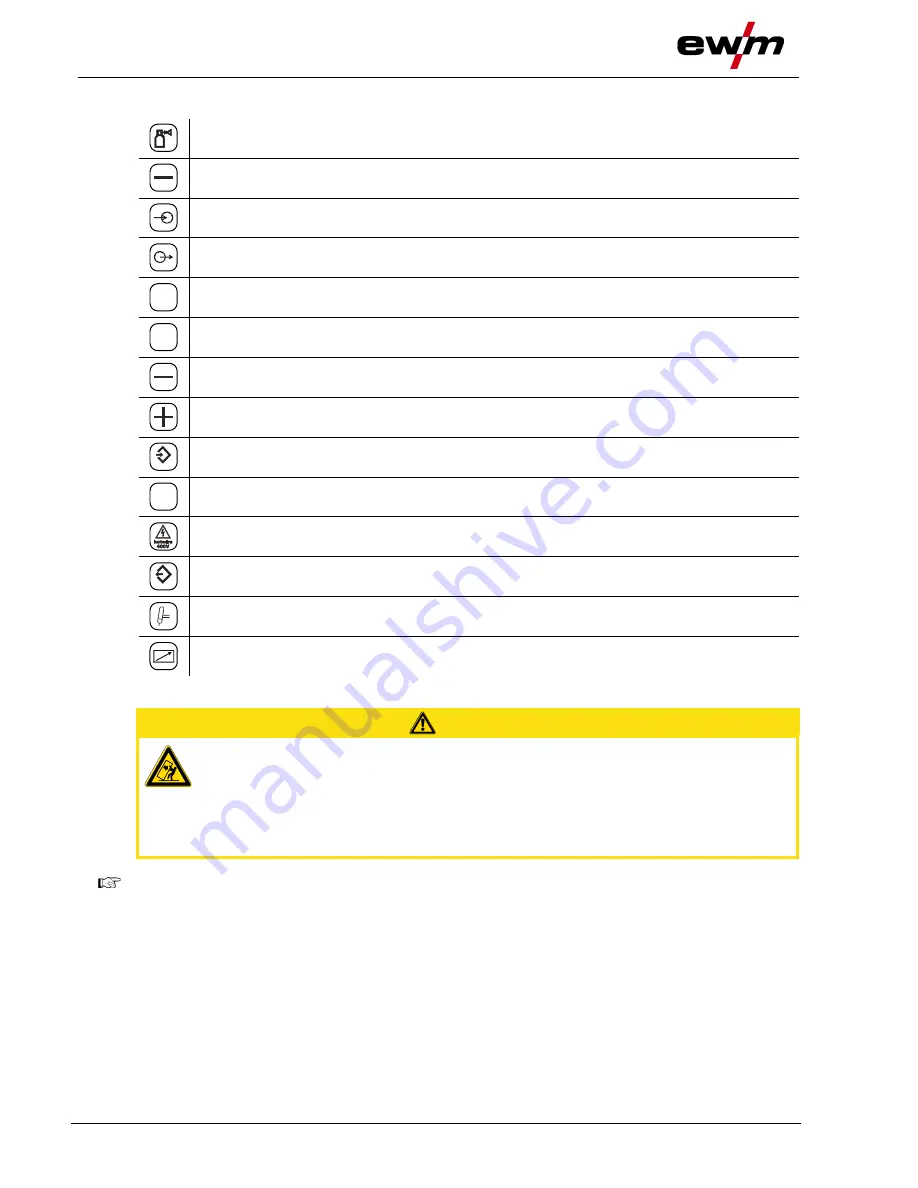

Legend

Shielding gas

Welding current(minus potential)

Coolant input (marked in colour)

Coolant output (marked in colour)

X2

Control lead (28-pole)

TP

Hose package (TP = tube package)

HW

Welding current (minus potential, TIG hot wire)

Welding current (plus potential, workpiece)

hotwire

Control lead, hot wire (signal input, 4-pole)

3~

AC

Connection, supply voltage (3-phase)

Supply voltage, hot wire power source

hotwire

Control lead, hot wire (signal output, 4-pole)

Control lead, welding torch (12-pole)

Remote control connection

5.9.3

Installation

CAUTION

Installation site!

The machine must not be operated in the open air and must only be set up and

operated on a suitable, stable and level base!

• The operator must ensure that the ground is non-slip and level, and provide sufficient

lighting for the place of work.

• Safe operation of the machine must be guaranteed at all times.

In a TIG cold wire welding system the wire feed unit is placed onto the casing cover of the TIG

power source.