Design and function

MIG/MAG welding

36

099-005507-EW501

13.09.2018

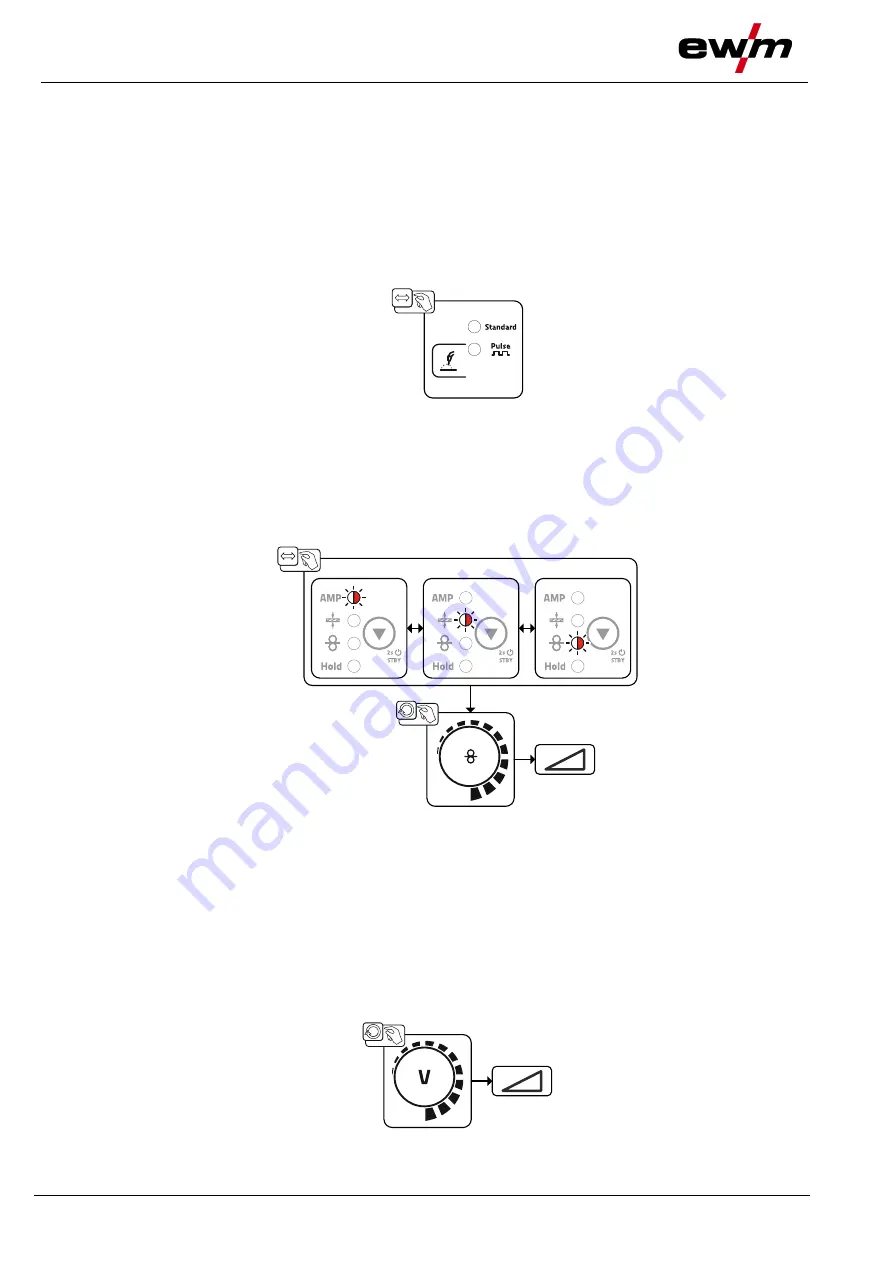

5.4.4.3 Welding type

Different forms of MIG/MAG processes are collectively referred to as welding type.

Standard (welding with standard arc)

Depending on the set combination of wire feed speed and arc voltage, the arc types short arc, transitional

arc or spray arc can be used for welding.

Pulse (welding with pulsed arc)

A selective change in the welding current generates current pulses in the arc, which lead to a 1 drop per

pulse of material transfer. The result is an almost spatter-free process, suitable for welding of all

materials, in particular high-alloy CrNi steels or aluminium.

Figure 5-18

5.4.4.4 Welding power (operating point)

The welding power is adjusted according to the principle of one-knob operation. The user can set their

operating point optionally as wire feed speed, welding current or material thickness. The optimum welding

voltage for the operating point is calculated and set by the welding machine. If necessary, the user can

correct this welding voltage

> see 5.4.4.6 chapter

.

?

Figure 5-19

5.4.4.5 Accessory components for operating point setting

The operating point can be set at various accessory components as well, such as remote control, special

welding torches or robot and industrial bus interfaces (optional interface for automated welding required,

not available for all machines of this series).

See the operating instructions for the machine in question for a more detailed description of the individual

machines and their functions.

5.4.4.6 Arc length

When required, the arc length (welding voltage) can be adjusted for the welding task in hand by +/

– 9.9 V.

Figure 5-20