Design and function

MIG/MAG welding

099-005507-EW501

13.09.2018

35

5.4.3

Definition of MIG/MAG welding tasks

This machine series offers user-friendly operation and a multitude of features.

• Various welding tasks (JOBs) consisting of welding procedure, material type, wire diameter and

shielding gas type have been predefined

> see 11.1 chapter

.

• The system calculates the required process parameters depending on the operating point specified

(one-knob operation via wire feed speed rotary transducer).

• You can adjust additional parameters at the machine control or using the PC300.NET welding

parameter software, if required.

Phoenix Expert machine series:

The welding task is set at the power source control; refer to the relevant system documentation.

If required, the predefined special welding tasks SP1 = JOB 129 / SP2 = JOB130 / SP3 = JOB 131 only

can be selected at the wire feeder control. The special JOBs are selected by pressing the welding task

selection push-button for a longer period. The special JOBs are switched by pressing the push-button

briefly.

5.4.4

Welding task selection

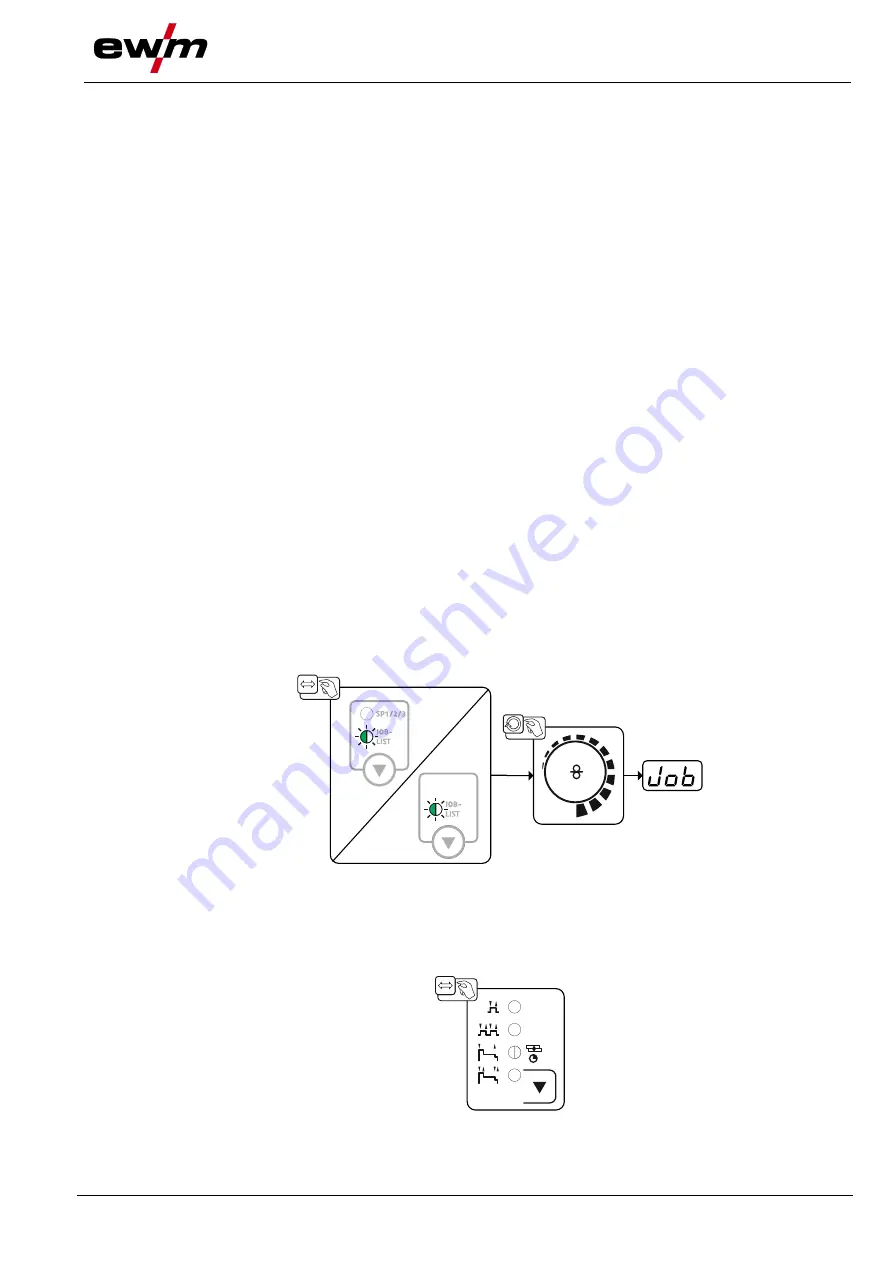

The following steps have to be carried out to select the welding job:

• Select basic parameters (material type, wire diameter and shielding gas type) and welding procedures

(select and enter JOB number by means of JOB-List

> see 11.1 chapter

).

• Select operating and welding type

• Adjust welding power

• Correct arc length and dynamics if necessary

• Adjust expert parameters for special applications

5.4.4.1 Basic welding parameters

The user must first determine the basic parameters (material type, wire diameter and shielding gas type)

of the welding system. These basic parameters are then compared with the welding job list (JOB-LIST).

The combination of the basic parameters gives a JOB number, which must now be entered on the control

unit. This basic setting must be rechecked or adjusted only when changing the wire or gas.

You can only change the JOB number when no welding current is flowing.

Figure 5-16

5.4.4.2 Operating mode

The operating mode determines the process sequence controlled by the welding torch. Detailed

descriptions of the operating modes

> see 5.4.10 chapter

.

Figure 5-17