8

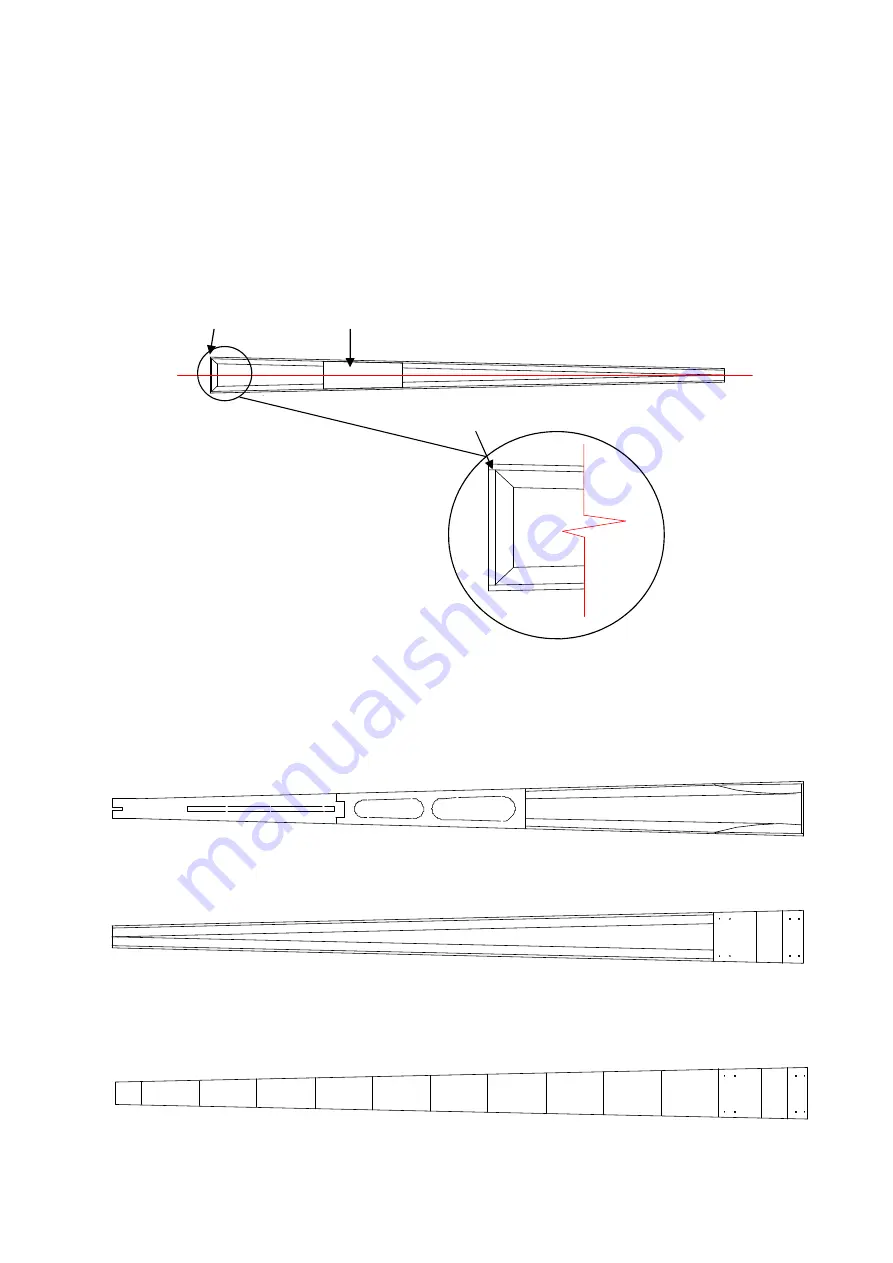

Glue the excess triangular fillet to the underside of F2 and dry fit between the Fuselage sides, ensure that F1

fits in the 3mm (1/8”) recess left at the front. If you are building the electric version carefully drill holes at the

top and the bottom of the former to allow air to enter the Fuselage for cooling.

F1 should be placed with the pre cut hole set towards the bottom of the Fuselage, once glued in place

chamfer the top and bottom to follow the Fuselage sides.

With F1 and F2 in place the Fuselage sides should taper back so that the triangular fillet at the rear just

touches. Once satisfied that the part fits correctly glue in place using epoxy. We have found this easier by

gluing F2 to one side of the Fuselage first and allowing to dry before offering the other side and inserting F1.

Ensure that F1 is 90° to the centre line of the Fuselage.

We have shown standard servos fitted in the Fuselage, but recommend that you use a good quality

mini/micro servo to reduce weight. Ensure the mini/micro servo is of the same or better specification as a

standard servo.

Once the epoxy has set, the top rear deck (Part 22) to the Fuselage, ensuring the rear Fuselage remains

square and the cut out for the Fin remains along the Fuselage centre line.

With epoxy glue the front ply (Part 26), centre balsa (Part 2) and rear ply (Part 28) undercarriage plates into

position.

With the supplied the sheet of 3mm (1/8”) balsa plank the front top deck of the Fuselage. If you are building

the

glow version

continue to plank the whole of the bottom. The planking grain should run from side to side

to provide maximum strength.

CL

F1

F2

F1 set flush with front of

fuselage, triangular fillet set

back 3mm to allow this

.

3mm