Make sure that it is functioning normally at 220 V and the power source is properly grounded.

Check the emergency stop button.

The button is not pressed down by default. If it is pressed, rotate the button clockwise to return

theoriginalstate.

Check the leadcurtains.

Make sure the lead curtains hang normally. Contact the manufacturer if the lead curtain

is drops down.

Remove items from the tunnel.

4.2

Power-On and Startup

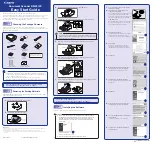

Table 4-1 Components

No.

Image

Name

Function

1

Power plug

Supply power.

2

Key switch

Turn on and turn off the Machine.

3

Start button

Start the Machine.

4

Emergency stop button

Immediately stop the X-ray source and

conveyor belt if an emergency occurs.

5

Indicator

Green: Power indicator.

Red: X-ray indicator.

Hardware Operation

Step 1 Connect the triangle plug to the socket.

Step 2 Turnon the Machine. Insert the key into the key switch and rotate it

clockwise.

Step 3 Start the Machine by pressing the start button, and then the power indicator

will turn on.

After the Machine starts normally, it goes to the operation interface.

Software Operation

Step 1 Turn on the software system, and then the self-check starts. A prompt box will

appear reminding you that the calibration is in progress. The X-ray indicator is

on during the calibration and will switch off after the calibration.