25

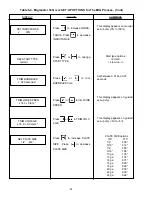

Use

or

to change PLATE SIZE.

Note: PLATE SIZE options are listed in Table 4-3.

Trim voltage after you test weld and want to adjust arc length.

Press

to increase voltage or

to decrease.

Trim wire speed after you test weld and want to adjust heat.

Press

to increase wire feed speed or

to decrease.

The voltage setting will automatically change with the

change in wire feed speed.

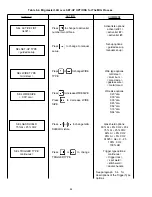

Table 5-3. Migmaster 300i cvcc GUIDED SET-UP for the MIG Process

Display

Action

Connect the MIG Torch and Work lead.

Select MIG on the front panel selector switch.

Power on unit.

Set shielding gas flowmeter to 35 cfh.

Use

or

to change WIRE TYPE to desired material.

Note: Wire Type Options are listed in Table 4-3.

Use

or

to change WIRE SIZE to desired diameter.

Note: WIRE SIZE options are listed in Table 4-3.

Use

or

to change GAS SHIELD to desired mixture.

Note: GAS SHIELD options are listed in Table 4-3.

SEL WIRE SIZE

.035" dia

SEL GAS SHIELD

75% Ar + 25% CO

2

SEL PLATE SIZE

1/4" .250"

TRIM VOLTAGE

v

^

SEL WIRE TYPE

mild steel >

TRIM WIRE SPEED

v

^

The shaded boxes are the only selections required to be modified by the operator when using the guided set-up mode.

The non-shaded boxes provide advanced settings or other special functions and are detailed under the Migmaster 300i

setup options for MIG process Table 5-4.