11

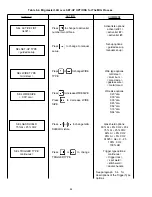

3.3.2 OPERATIONAL DESCRIPTION OF DISPLAY

The display screen presents a two-line alphanumeric

display. The upper line displays the main control func-

tion and the lower line displays the selections and set-

tings made. Additionally, the upper line indicates mea-

sured data during welding and holds this data until

changed by the keypads.

The right and left keypads are used to increase and

decrease the setting of parameters. The arrow point-

ing up on the right keypad indicates an increase in pa-

rameter value while the arrow pointing down on the left

keypad indicates a decrease in parameter value.

The keypads are also used to select between different

choices. For this operation, the right keypad selects

choices to the right as indicated by the arrow. Like-

wise, the left keypad will select choices to the left as

indicated by the arrow. The middle keypad is used to

step to the next line in a list to be changed.

Finding and setting a welding condition is an iterative

process. This means that one or more parameters

are tuned to reach a desired result. Tuning means

that the value of a parameter is changed, a test weld is

performed, and based upon the test weld results, the

operator will either change the setting or select another

parameter to tune. This process continues until a sat-

isfactory welding condition for the job is found.

To make this process effective with as few controls as

possible, all parameters are stored in a dynamic list.

The order of the parameter list is based upon whether

or not the value is changed. This will always keep the

most likely parameter to be changed accessible and

the second most likely parameter to be the next pa-

rameter to be accessed. Changing a parameter will

put that parameter line on top of the list. Not changing

the parameter will leave it in its position. This applies

only to MIG set parameters such as voltage, wire feed

speed, inductance, spot time, etc. In this way, the it-

erative process of finding a set of welding parameters

will be accelerated.

To limit the number of lines in the list, only those items

selected are present in the list. If SEL SET-UP TYPE

is "guided mode" you will find lines in the list that will

allow the operator to specify wire type, wire size, shield-

ing gas, plate size, voltage trim, and wire speed. If

"manual mode" is selected, SEL SET-UP TYPE will

disappear and the operator will find lines allowing the

setting of voltage, wire feed speed, and inductance.

When the operator starts to weld or hits the torch switch,

the top of the list is displayed. An overview of the total

setting is made by stepping down the parameter list.

(It is only possible to step down the list and set or se-

lect.) Notes may be made in the free space of the

front panel.

3.3.3 OPERATIONAL PROCEDURE OF DISPLAY

A. The upper line shows the main control func-

tion; SELect an item or SET a parameter.

B. The middle keypad advances the display to the

next line of parameters in the list. The bottom

line shows the present (active) SELection or

SETting. If this is satisfactory, and another

item is desired, press the middle keypad again.

C. If the left or right keypad is pressed, the

SELection is changed. A SET value of a

parameter is set by pressing the left (decrease)

or right (increase) keypad again. One of the

following will occur the next time the middle

keypad is pressed:

1. If other lines are dependent on the

SELection made, they will appear the next

time the middle keypad is pressed.

2. A change of a parameter that the operator

SET will put that parameter at the top of

this list the next time the middle keypad is

pressed and the list will move down a line.

The next line will be displayed (not the

second in the list). If the torch switch is

pressed instead of the middle keypad, the

changed parameter at the top of the list

will be displayed.

D. When the torch switch is pressed and/or weld-

ing starts, the display's lower line shows the

last SET item. The upper line shows measured

data (normally current and voltage).

E. After welding, the upper line returns to the main

control function text when any of the three

keypads are pressed the first time.

F. If a SET parameter is in the lower line of the

display during welding, the left (decrease) and

right (increase) keypads may be used. The two

knobs on the torch or pendant may be used to

change the parameters since they have the

same function as the left and right keypads.