13

3.7 SAVING WELDING CONDITIONS

If a job is to be repeated at a later time, it may be de-

sired to save the welding conditions just completed.

To make this possible, the MigMaster 300i has three

lists, each containing a complete MIG setup. One of

the three lists is always active. The line SEL ACTIVE

LIST shows which list is active. If the "active list #1"

shows on the lower line of the display while scrolling

through the list, it means that the whole list is list num-

ber one.

If the Power Source is set up for a job and the operator

desires to come back to these settings later, change

the active list to number 2 or 3 with the right keypad.

Now a new set of parameters can be set up for an-

other job. Returning to the parameters of the first job

is done by stepping through the list with the middle

keypad to the upper line of SEL ACTIVE LIST and us-

ing the left keypad to SELect "active list #1".

3.8 FAULT CONDITIONS

The operating parameters of the MIGMASTER 300i

Power Source is continuously monitored without inter-

fering with the operator. The control circuit monitors

the following:

A. Main input voltage for over or under voltage

conditions.

B. Thermal switches (TS1 and TS2) and power

output to prevent Power Source overheating.

C. Wire feeder motor (M2) speed.

D. Electrical function of the inverter power unit.

In the event the monitoring activity detects any out-of-

tolerance conditions, the operation in progress is inter-

rupted and the display indicates what the problem is in

the following manner:

A. Top row shows "DETECTED A FAULT".

B. Bottom row indicates the problem.

It may be difficult to see the message on occasion due

to the function of the screen displaying the measured

values of the current welding process. The informa-

tion is easy to find because it is a line in the list and

when the operator scrolls through the list, the mes-

sage line will show up as one of the lines in the list.

When the displayed problem(s) are corrected, the mes-

sage will disappear and operation may be resumed.

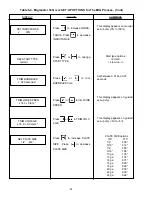

Table 3-1. Parameter Defaults

In MIG process:

Top row

Bottom row

SEL SET-UP TYPE

SEL WIRE TYPE

SEL WIRE SIZE

SEL GAS SHIELD

SEL PLATE SIZE

TRIM VOLTAGE

TRIM WIRE SPEED

SEL TRIGGER TYPE

SEL START TYPE

TRIM BURNBACK

SEL ACTIVE LIST

guided mode

mild steel

.035" dia.

90Ar+8C02+202

16ga .060"

14.8 +0.0 volts

125 +0ipm

continuous

normal

0.20 seconds

list #1

In TIG process:

Top row

Bottom row

SET CURRENT TIG

SET PRE FLOW

SET POST FLOW

60 amps

0.5 seconds

12.0 seconds

In STICK process:

Top row

Bottom row

0 Amp 51.0 Volts

STICK 120 amps

The only exception to this is the fault "high current". In

this case, the Power Source will have to be shut down

(off) and a service representative contacted.

If during welding, a short circuit (i.e., frozen electrode)

is maintained longer than normal, a safety function limits

the output. Once the short is removed, the operation

will return to normal.

To display the default settings, press the left and middle

keypad and turn power switch to ON (while holding

keypads down). This action will give the default set-

ting of the lists. The complete setting of all parameter

defaults are shown in Table 3-1.