11/12

888-24-090-G-00 rev. D • 11/10

EN

Maintenance & Safety

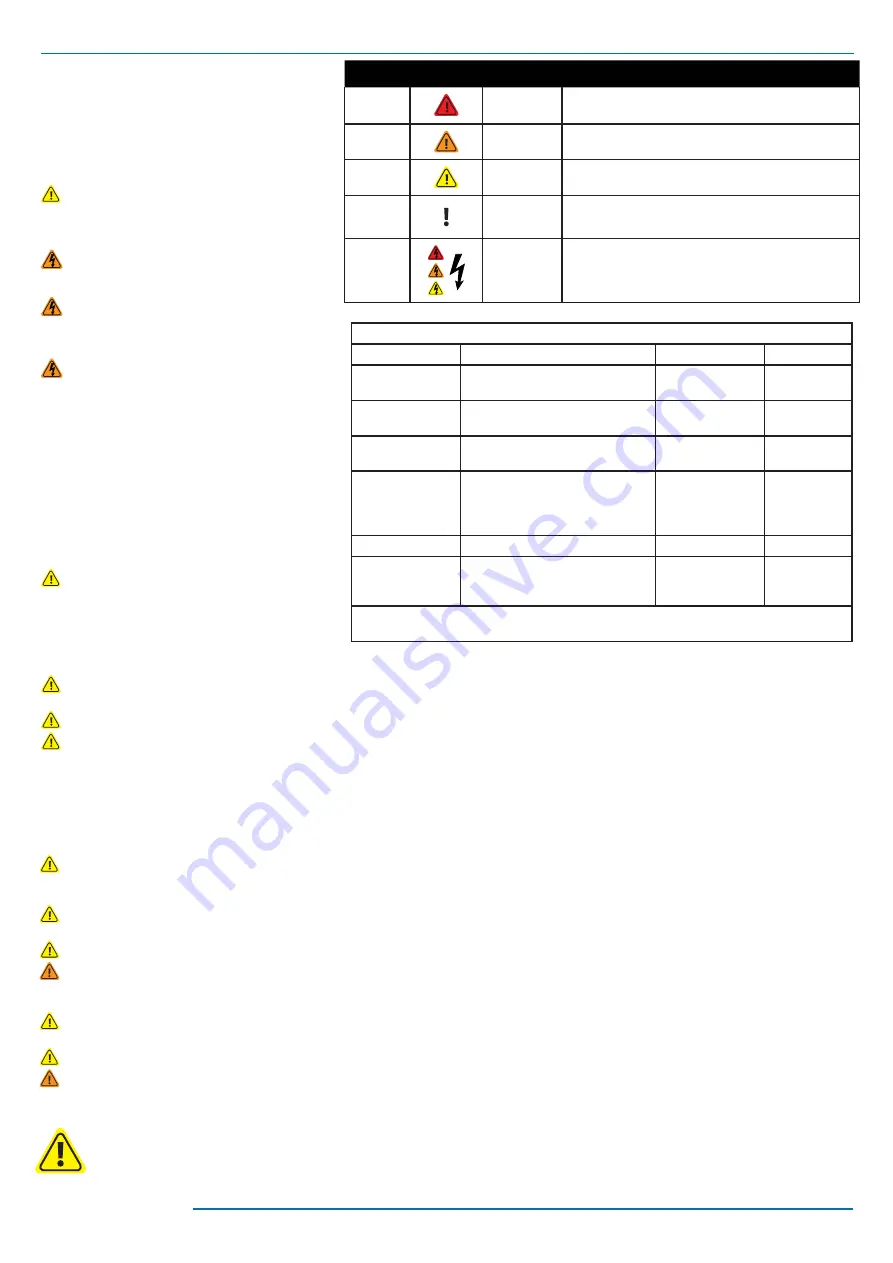

Color

Symbol

Signal Word

Level of Hazard

Red

DANGER

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Orange

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Yellow

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

None

CAUTION

Used without the safety alert symbol indicates a potentially hazardous situa-

tion which, if not avoided, may result in property damage.

Red,

Orange

or Yellow

Electrical

Indicates an impending electrical hazard which, if not avoided,

may result in personal injury, fi re and/or death.

Hazard Symbols Review

The Meaning of Symbols appearing in this Guide, on the Cart

or on the Power System

These symbols alert you to a safety condition that

demands your attention. You should be able to recognize

and understand the signifi cance of the following Safety

Hazards if you encounter them on the Cart or within Cart

documentation such as this Set-up Guide.

EQUIPMENT & ACCESSORIES DISPOSAL

1. Please dispose of all batteries in accordance with local law

2. User Interface, Auto-lock Drawer, and Ready On Module should be recycled through an electronics recycler.

3. Remaining plastics and metals can be recycled through a commercial recycler.

Cleaning and Maintenance

The following procedures are not guaranteed to control infection.

The hospital infection control administrator or epidemiologist

should be consulted regarding cleaning procedures and processes.

To avoid risk of electric shock, do not expose electrical

components to water, cleaning solutions or other potentially

corrosive liquids or substances.

Do not immerse Cart or Cart components in liquid or

allow liquids to fl ow into the Cart. Wipe all cleaners off surface

immediately using a damp cloth. Thoroughly dry surface after

cleaning.

Do not use fl ammable cleaners on Cart surfaces due to close

proximity of electrical power and equipment.

All painted and plastic Cart components will withstand cleaning

by most commonly used, diluted, non-abrasive solutions such as

quaternary ammonia compounds, ammonia enzyme cleaners,

bleach or alcohol solutions.

• Pen and permanent and dry erase markers can be removed with

91% isopropyl alcohol and a soft cloth.

• Iodine stains can be removed with commonly used cleaners and

a soft cloth.

• Never use steel wool or other abrasive materials that will damage

the surface fi nish.

• Do not use strong solvents such as trichloroethylene and acetone.

These solvents will damage the surface fi nish.

It is recommended that any cleaning solution be tested on a small,

inconspicuous area to ensure surface is not harmed.

Adjustment, Service, Replacement - DO NOT attempt to

adjust, service or replace any part of the StyleView Cart unless

directed to do so through Ergotron-approved documentation

(i.e. installation instructions). Only Ergotron, Inc. or an Ergotron-

certifi ed entity may adjust, service or replace StyleView Cart

components. If any component on the Cart is missing or damaged,

the Cart must not be used, contact Ergotron Customer Care immediately to request a replacement part.

Cables - Keep cables neatly organized on the Cart (a variety of solutions are provided with your cart for this purpose). Excess cables should be routed away from moving

components with cable clips. Review Cable Routing section of this guide, or contact Ergotron Customer Care for more information.

Casters - Check casters periodically to make sure they are clean and free of debris that would prevent smooth travel. Avoid moving Cart across uneven, dirty or damaged surfaces.

Customer Equipment- Make sure equipment is balanced and mounted securely to Cart. Do not reposition Cart components on riser or tower unless instructed to do so in the

installation instructions. Moving Cart components too high or too low on the Riser may create an unstable condition, leading to equipment damage or even personal injury. Contact

Ergotron Customer Care for information about moving Cart components.

Safety Alerts Associated with this Product

The following Warnings/Cautions appear in this reference guide or on the cart:

NOTE: Failure to adhere to these guidelines may result in equipment damage or personal injury.

CAUTION: The lift brake helps stablilize the worksurface and keyboard tray during normal use but it DOES NOT increase load capacity. DO NOT load riser with equipment

totalling more than the maximum weight capacity specifi ed by Ergotron. Ensure optimum lift function by testing and if necessary, re-adjusting tension whenever the weight

mounted to the riser changes (i.e., equipment is removed or added). See "Set Riser Lift Tension" adjustment instructions.

CAUTION: Do not operate StyleView Cart with missing or damaged components! Do not remove, modify or substitute Cart components without consulting Ergotron. If you

encounter problems with Cart installation or operation, contact Ergotron Customer Care.

CAUTION: DO NOT overtighten fasteners. Overtightening may cause damage to your equipment.

WARNING: Stored Energy Hazard: The worksurface lift mechanism is under tension and will move up rapidly, on its own, as soon as attached equipment is removed. For this

reason, DO NOT remove equipment unless the worksurface has been moved to the highest position on the tower! Failure to follow this instruction may result in serious personal

injury and/or equipment damage! When Shipping the cart, set the worksurface lift mechanism to the lowest tension setting.

CAUTION: DO NOT loosen, tighten or remove any other nuts or bolts on the riser or top of tower. Tampering with nuts or bolts may result in an unstable Cart, leading to

equipment damage and/or personal injury.

CAUTION: Release Lift Brake before moving work surface! Moving work surface while Lift Brake is engaged may cause serious damage to Lift Engine.

WARNING: In the event that repair of the StyleView Cart is needed, contact Ergotron Customer Care immediately. Cart repair can only be performed by Ergotron, Inc. or by an

Ergotron authorized agent.

Recommended Periodic Inspection and Maintenance

Component

Action

How often

By whom

ALD Batteries

(SV31 only)

Replace 4 ea AA NiMH batteries

1

Replace when

keypad #4 fl ashing

Any user

Ready On Batteries

(SV31 only)

Replace 2 ea AA Lithium batteries

1

Replace when light

on Ready On fl ashing

Any user

UI, Ethernet, USB

cables

Inspect for wear, pinching, bad

connectors

Monthly

Any user

Fan on side of CPU

compartment

Inspect for dust at intake, vacuum

as required using a vacuum cleaner

that DOES NOT generate ESD

(Electrostatic Discharge)

Monthly

Any user

Casters

Inspect for wear and debris

Monthly

Any user

Maximum Load

Inspect to ensure that maximum

recommended loads are not

exceeded

Daily

Any user

1. Please dispose of all batteries in accordance with local law

2. Always replace with similar size battery (33 A-h to replace 33 A-h) and always replace in pairs