1/2" AIR RATCHET WRENCH

VIBRATION

The European Physical Agents (Vibration) Directive has been brought in to help

reducehand arm vibration syndrome injuries to power tool users. The directive requires

power tool manufacturers and suppliers to provide indicative vibration test results to

enable users to make informed decisions as to the period of time a power tool can be

used safely on a daily basis and the choice of tool.Further Advice can be found at

www.hse.gov.uk

The declared vibration emission value should be used as a minimum level should be

used with the current guidance on vibration.

Calculating the actual period of the actual period off use can be difficult and the HSE

website has further information.

The declared vibration emission been measured in accordance with a standardised

test stated above and may be used to compare one tool with another.

The declared vibration emission value may also be used in a preliminary assessment

of exposure.

- The declared vibration total value has been measured in accordance with a standard

test method and may be used for comparing one tool with another.

- The declared vibration total value may also be used in a preliminary assessment

of exposure.

TECHNICAL SPECIFICATIONS

WARNING! The vibration emission during actual use of the power tool

can differ from the declared total value depending on the ways in which

the tool is used; and of the need to identify safety measures to protect the

operator that are based on an estimation of exposure in the actual

conditions of use (taking account of all parts of the operating cycle such

as the times when the tool is switched off and when it is running idle in

addition to the trigger time).

NOISE AND VIBRATION DATA

Sound pressure level LPA: 87 dB (A) (K=3dB(A))

Sound power level LWA: 98 dB (A) (K=3dB(A))

Vibration level: 4.35m/s

2

(K = 1.5m/s

2

)

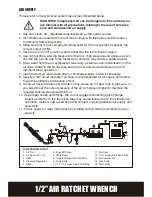

SPECIFICATIONS

COMPONENT

1/2"

160rpm

60Ft-Lb (85Nm)

1/4" BSP

3/8"

4cfm

90psi (6.3bar)

Square drive

Maximum no load speed

Maximum torque

Air inlet

Air hose (inner diameter)

Average air consumption

Working pressure

Summary of Contents for ERN634ATL

Page 1: ...1 2 AIR RATCHET WRENCH ERN634ATL...

Page 16: ...1 2 AIR RATCHET WRENCH...