1/2" AIR RATCHET WRENCH

OPERATION

5

H

4

H

A

G

6

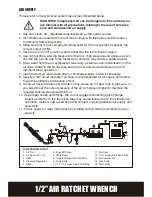

4. Choose the correct impact socket

(not provided) as needed and mount it onto

the anvil (H). (See Figure 4)

1. How to install/tighten threaded fasteners.

Turn the F/R knob (A) counterclockwise to “F”

position (F=Forward or Tighten). Press the

trigger (G). The tool anvil (H) runs clockwise.

(See Figure 6)

5. Connect air supply hose to the male plug.

(See Figure 5)

WARNING! Only use impact sockets

that have a RPM and Torque rating

equal to or greater than the tool itself.

6. Set the working pressure at 90psi/6.3bar for

best tool performance.

NOTE:

Working pressure refers to the

air line pressure set to tool when tool

is under working conditions.

Summary of Contents for ERN634ATL

Page 1: ...1 2 AIR RATCHET WRENCH ERN634ATL...

Page 16: ...1 2 AIR RATCHET WRENCH...