1/2" AIR RATCHET WRENCH

WARNING! Compressed air can be dangerous. Ensure that you

are familiar with all precautions relating to the use of compres-

sors and compressed air supply.

1. Use only clean, dry, regulated compressed air as the power source.

2. Air compressors used with the tool must comply with the appropriate European

Community Safety Directives.

3. Make sure that the air compressor being used for the tool operation supplies the

correct output (CFM).

4. Have the tool in "off" position when connecting the tool to the air supply.

5. Use normal 90psi working pressure for the tool. High pressure and unclean air will

shorten the tool life due to the faster wear and also may create a safety hazard.

6. Drain water from the air compressor tank daily, as well as any condensation in the

air lines. Water in the air line may enter the tool and cause damage to the tool

mechanisms at operation.

7. Clean the tool air inlet screen filter for blockage weekly. Clean if necessary.

8. Usually a 3/8" (inner diameter) air hose is recommended for air supply and airflow

to get the optimum performance of tool.

9. A long air hose (usually over 8 meters) may cause up to 15psi drop in pressure, so

you need to set the output pressure of the air compressor higher to maintain the

required working pressure at the tool.

10. Use proper hoses and fittings. We do not suggest connecting quick change

couplings directly to the tool since they may cause failure due to tool vibration at

operation. Instead, add a lead hose and connect coupling between air supply and

hose whip.

11. Check hoses for wear before each use. Make certain that all connections are in

security.

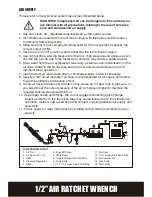

AIR SUPPLY

6. Shut Off Valve

7. Whip Hose

8. Coupler Body And Connector

9. Drain Daily

10. 1/2" Or Larger Pipe And Fitting

AIR SYSTEM LAYOUT

:

1. Air Tool

2. Air Hose 3/8" (I.D.)

3. Oiler

4. Pressure Regulator

5. Filter

11. Air Dryer

12. 1" Or Larger Pipe And Fitting

13. Air Compressor

14. Auto Drain

15. Drain Daily

6

9

13

14

15

8

7

12

10

5

4

3

2

11

1

Please refer to the typical air system layout recommended below.

Summary of Contents for ERN634ATL

Page 1: ...1 2 AIR RATCHET WRENCH ERN634ATL...

Page 16: ...1 2 AIR RATCHET WRENCH...