EPSON Stylus COLOR 880

Revision A

Troubleshooting

Overview

66

5

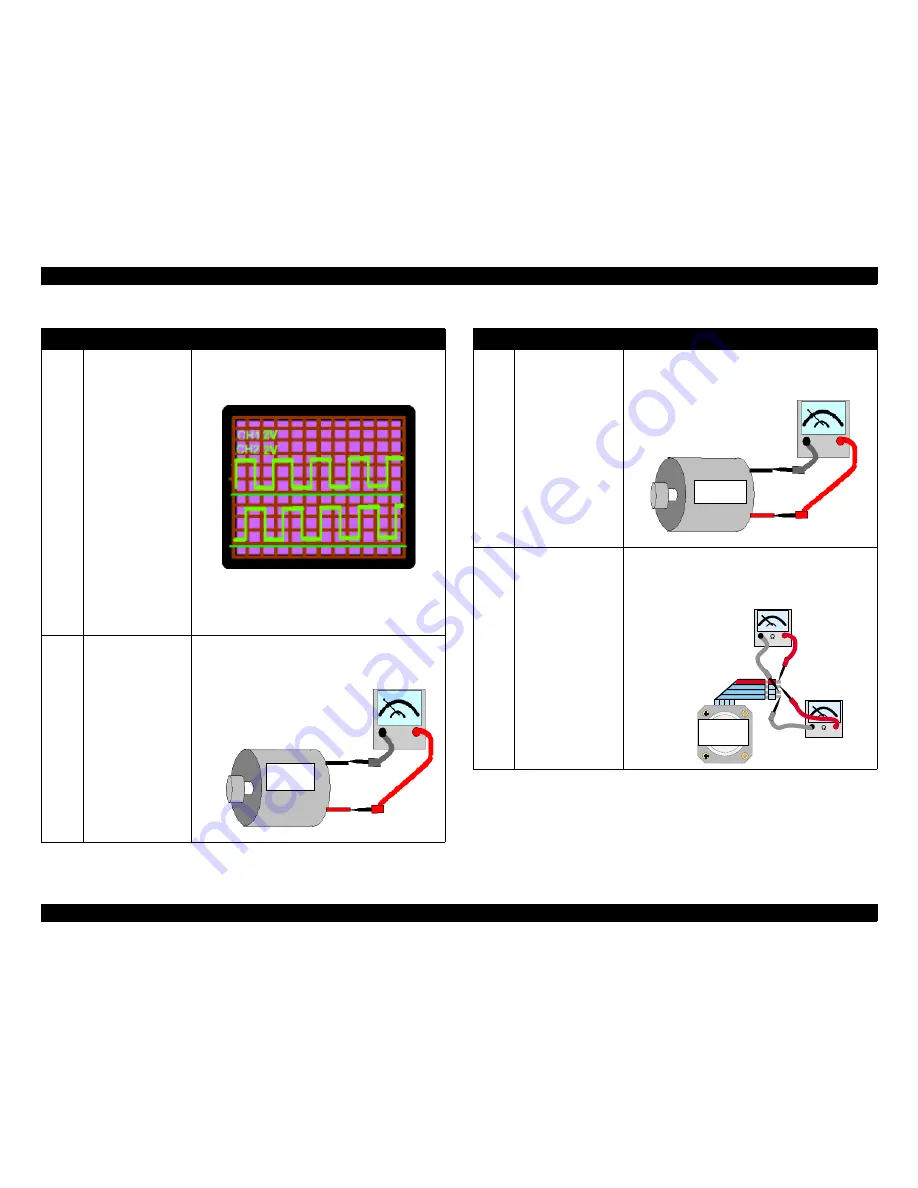

When the Printer is

turned on, the CR

move a little and the

PF motor also moves

little.

After that, the Panel

LED indicates the

Fatal Error.

• Check for the correct waveform at 5 pins of FFC.

The PF Motor Encorder Sensor FFC is connected

to CN12 on the C378 Main Board. Check that both

connectors Pin 1 & 4 or Pin 1& 2.

• Check for the correct wavehorm at 21pins of Head

FFC. The Head FFC is connected to CN8 on the

C378 Main Board. Check that both connectors Pin

2 & GND or Pin 4& GND.

6

When the Printer is

turned on, the CR

motor dose not move

at all. (PF motor

moves.)

After that, the Panel

LED indicates the

Fatal Error

Since the CR motor is DC motor, measure the coil

resistance using the tester as following figure

<Resistance: 31.1

Ω

±

25%>

Table 3-9. Remedies for Fatal Error (continued)

Step

Detail Phenomenon

Check & Actions

CR Motor

7

When the Printer is

turned on, the PF

motor dose not

move.

After that, the Panel

LED indicates the

Fatal Error.

Since the PF motor is DC motor, measure the coil

resistance using the tester as following figure

<Resistance: 47.6

Ω

±

25%>

8

When the Printer is

turned on, it dose not

sound the ASF

Hopper moving.

After that, the Panel

LED indicates the

Fatal Error

Since the Pump/ASF motor is controlled by the

Bipolar system, measure the coil resistance using the

tester as shown below.

<Resistance: 10.4

Ω

±

10%>

Note: Be

sure to

measure the

resistance at

two points

shown in the

figure below.

Table 3-9. Remedies for Fatal Error (continued)

Step

Detail Phenomenon

Check & Actions

PF Motor

T o P i n 1

T o P i n 3

S t e p 1

S t e p 2

T o P i n 2

T o P i n 4

C R M o t o r

ASF/Pump

Motor

Summary of Contents for Stylus Color 880

Page 9: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 30: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 55: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 76: ...C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Page 116: ...C H A P T E R 5 ADJUSTMENT ...

Page 142: ...C H A P T E R 6 MAINTENANCE ...

Page 152: ...7 APPENDIX C H A P T E R ...

Page 177: ......

Page 178: ......

Page 179: ......