Item

Name

Explanation

Bi-D

Alignment

Adjusts differences in the print

position for bi-directional printing

for each color. It takes about 9 to 13

minutes to complete the

adjustments. The time required

varies depending on the menu

selected.

E

Select Auto or Manual.

When you select Auto, go to step 6.

When you select Manual, go to step 7.

Item

Name

Explanation

Auto

The sensor reads the adjustment

pattern printed on the paper, and

automatically registers the optimum

adjustment value to the printer. This

method is normally recommended.

Manual

Visually check the adjustment

patterns printed on the paper, and

enter the optimal adjustment values.

Use this if you cannot perform auto

adjustment, or if you are not satisfied

with the adjustment results when

using Auto.

F

Press

Start

to start adjusting the position of the

print head.

The sensor reads the adjustment pattern while it

is printing, and automatically registers the

optimum adjustment value to the printer.

When adjustment is complete, you are returned

to the screen displayed before head alignment

was performed. Check the adjustment results to

confirm if graininess or misalignment recurs in

the printed image.

If you are not satisfied with the results of the

adjustment, try adjusting manually.

G

Press

Start

to start adjusting the position of the

print head.

The adjustment pattern is printed on the loaded

paper.

Note:

Multiple adjustment patterns are printed for cut

sheets. Once printing the first sheet is complete,

load the next sheet of paper.

H

Check the printed adjustment pattern, and then

enter the set value into the control panel.

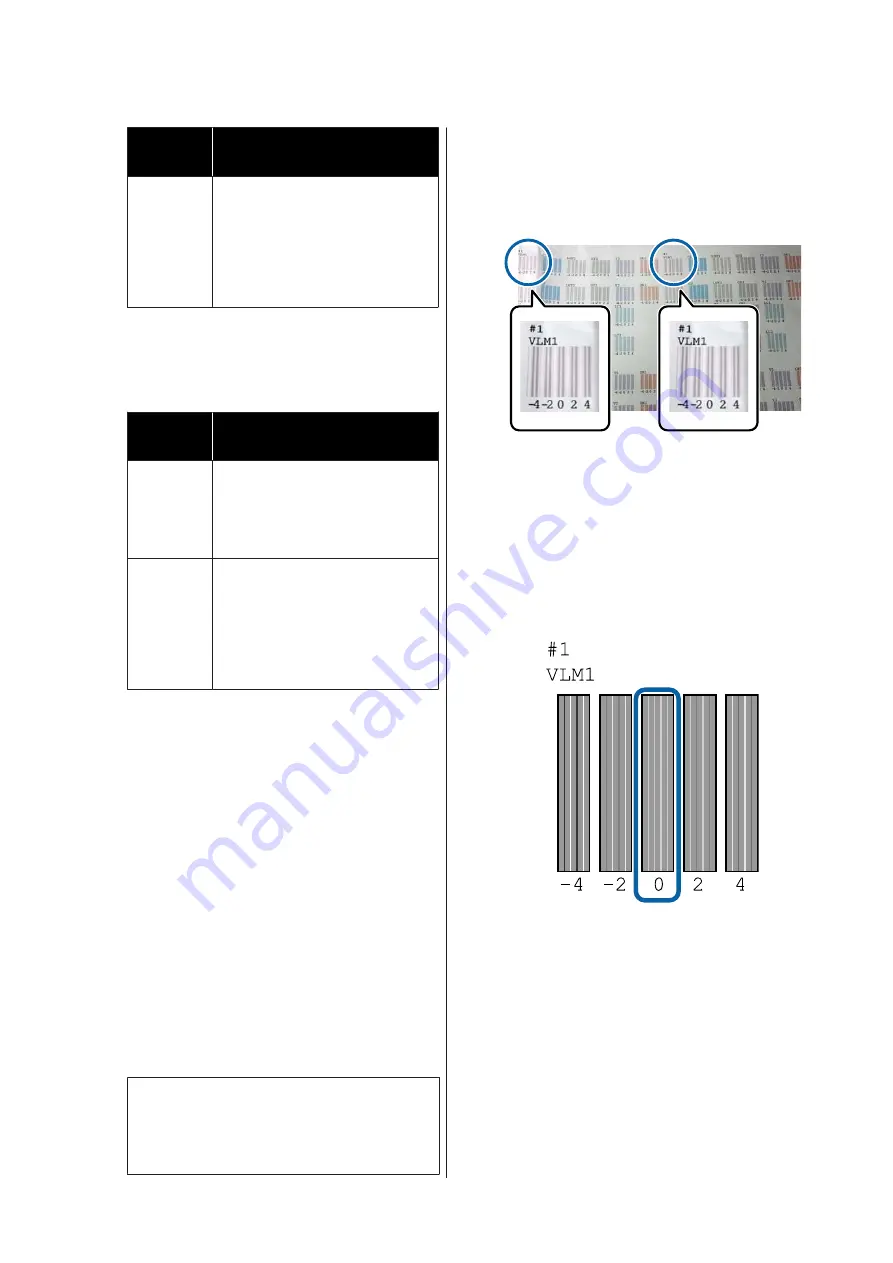

Uni-D Alignment

(1) Check the adjustment position for #1 VLM1.

In the photo above, you can see #1 VLM1 in two

places, but the number printed varies depending

on the paper width.

(2) Note the numbers of the patterns with the

fewest white lines or in which the white lines are

most evenly spaced.

In the following example image, "0" is the best

choice.

SC-P9500 Series/SC-P7500 Series User's Guide

Maintenance

120