FX-880 Service Manual

Chapter

3 Troubleshooting

Rev. A

3-1

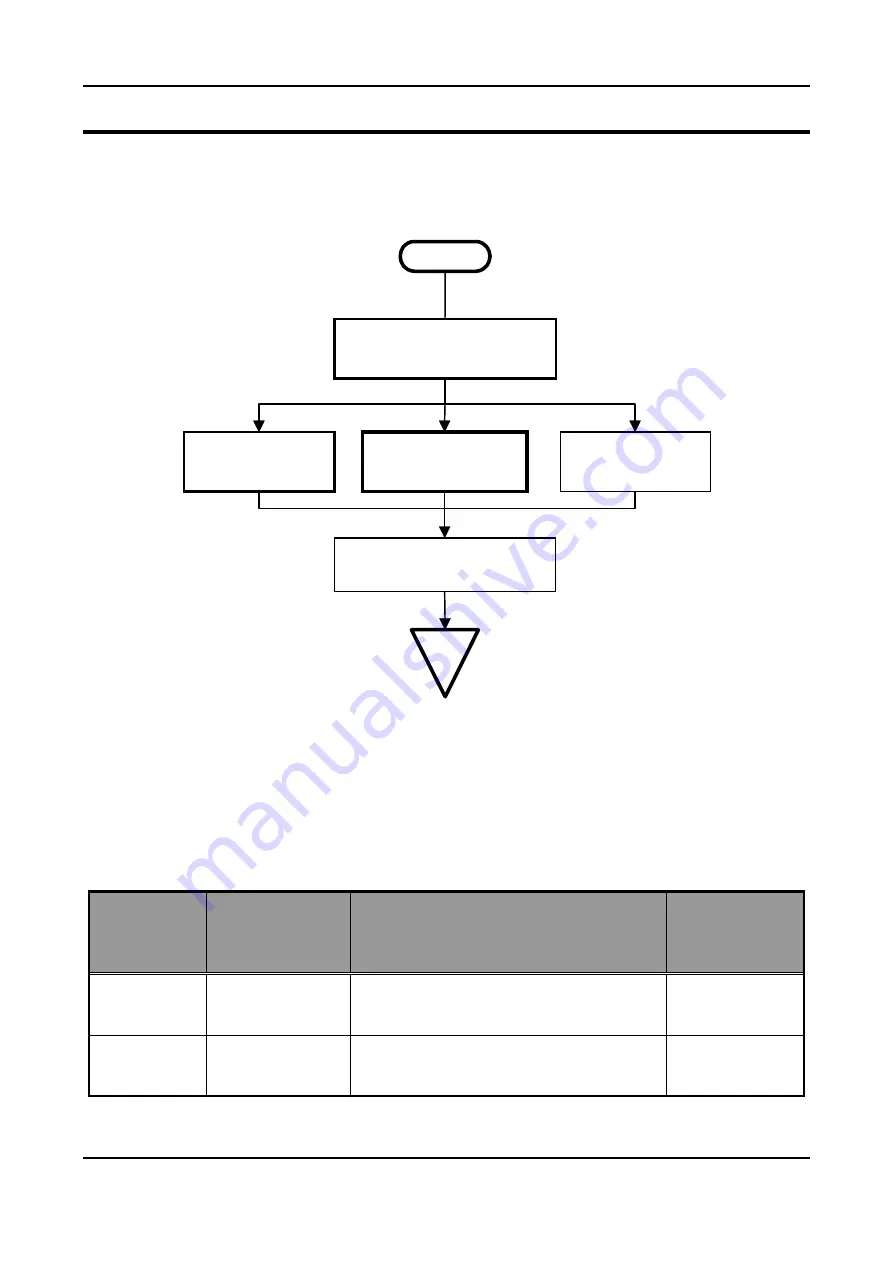

3.1 OVERVIEW

The printer may exhibit different symptoms for the same problem, which makes troubleshooting

more difficult. This section, however, provides simple and effective ways to facilitate

troubleshooting. The following flowchart illustrates the main steps of the troubleshooting process.

START

Unit Level Troubleshooting

Unit Repair of the

C229PSB/PSE Board

Unit Repair of the

C229MAIN Board

Unit Repair of

M-3J10 Mechanism

Assembly and Adjustment

END

Figure 3-1. Troubleshooting Process Flowchart

3.1.1 Main Component Checking Point

The following components can be checked by a simple measurement equipment such as a multi-

meter, etc.) easily.

Table 3-1. Motor Coil Resistance Test Points

Motor

Connector

Number

Test Pin

Number

Test Method

(Set Meter to Ohms. Disconnect

Motor from Main Board and check it

with Printer Power off.)

Meter Reading

PF Motor

(CN8)

1 and3, 2 and 4

Place one lead on pin 1 (pin2) and the

other lead on pin3 (pin 4) each of the

test pins to check the two motor phases.

16.0

Ω

±

10%

(at 25

°

C par one

phase)

CR Motor

(CN9)

Common pin : 5,

Test pins : 1, 2, 3

and 4

Place one lead on pin 5 and the other

lead on each of the 4 test pins to check

the two motor phase.

2. 7

Ω

±

10%

(at 25

°

C par one

phase)

Summary of Contents for FX-880 - Impact Printer

Page 1: ...6 59 0 18 3LQ PSDFW RW 3ULQWHU EPSON FX 880 4008484 ...

Page 5: ...REVISION STATUS Rev Date Page s Contents A 1997 09 30 All First release ...

Page 9: ...PRODUCT SPECIFICATION C H A P T E R 1 ...

Page 23: ...OPERATING PRICIPLES 3 7 5 ...

Page 30: ...TROUBLESHOOTING 3 7 5 ...

Page 49: ...DISASSEMBLY AND ASSEMBLY C H A P T E R ...

Page 72: ...ADJUSTMENT 3 7 5 ...

Page 80: ...MAINTENANCE 3 7 5 ...

Page 84: ...APPENDIX 3 7 5 ...

Page 92: ...FX 880 Service Manual Appendix Rev A 7 8 Figure 7 5 C229PNL Board Component Layout ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......