EPSON EPL-6200/EPL-6200L

Revision A

Adjustment

Feed Registration Adjustment

171

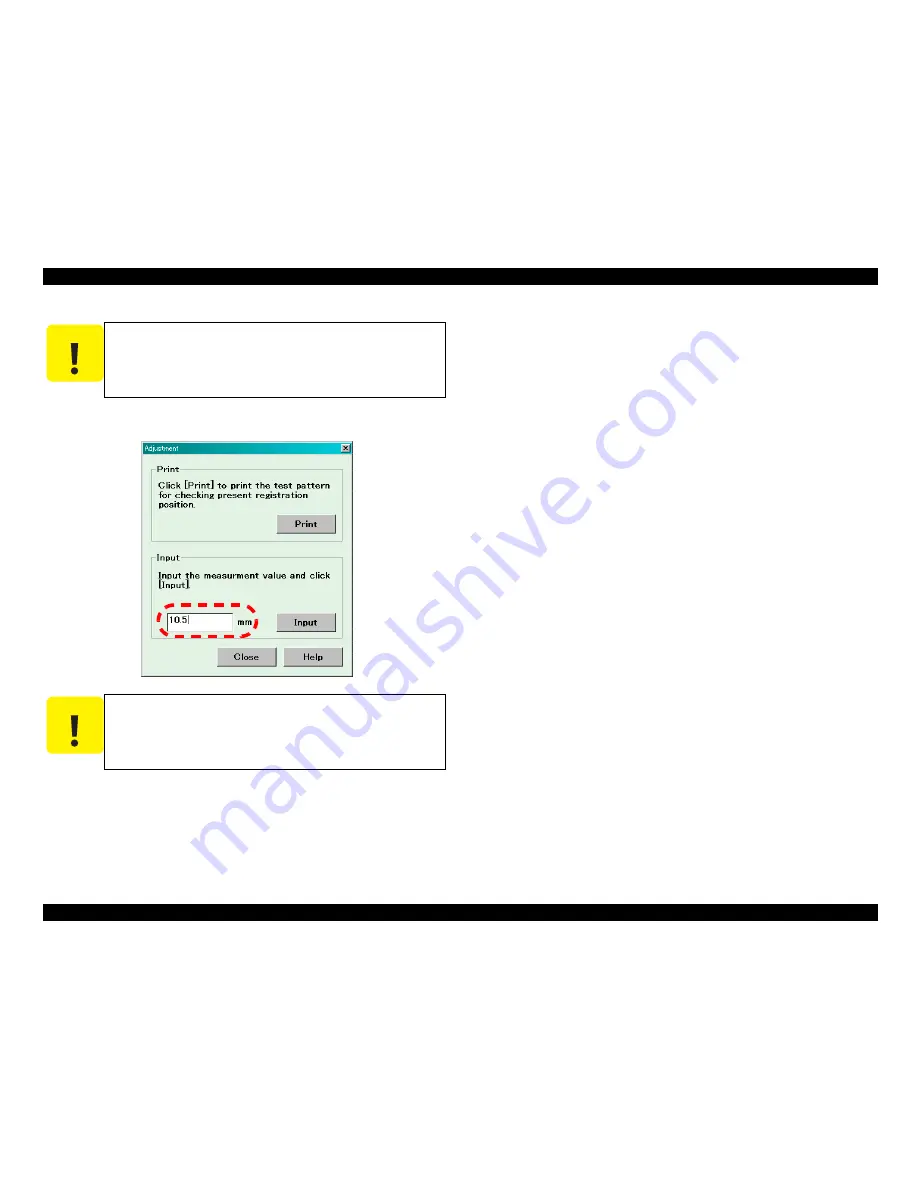

7. If the position is shifted, input the measured distance value in [Input] box and click

[Input] button to store the value on the main controller.

8. Click on [Print] button to print the pattern again with the specified correction value. If

further adjustment is required, go to <step 6> to repeat adjustment.

9. When the adjustment is finished, click on [Quit] button to terminate the program.

10. Turn off the printer.

C A U T I O N

Verify the registration position at both left and right side of the

pattern.

When printing a test pattern chart, make sure that the edge

guide of paper tray is properly aligned against the edge of paper

in order to avoid possible skew with fed paper.

C A U T I O N

If the input value is within the tolerance of adjust value, the

program displays a message and the value on the main controller

remains unchanged.

Summary of Contents for EPL-6200

Page 1: ...EPSON EPL 6200 EPL 6200L A4 Monochrome Page Printer SERVICE MANUAL ROSCO SEPG03002 ...

Page 7: ...Revision Status Revision Date of Issue Description A September 5 2003 First release ...

Page 12: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 67: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 99: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 129: ...C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Page 165: ...C H A P T E R 5 ADJUSTMENT ...

Page 172: ...C H A P T E R 6 MAINTENANCE ...

Page 175: ...C H A P T E R 7 APPENDIX ...

Page 180: ......

Page 181: ......

Page 182: ......

Page 183: ......

Page 184: ......

Page 185: ......