A

W-TRAC

IOM‐49

8 of 12

Mar 99 R4

If the outside air temperature is warmer than the exhaust air the W‐TRAC will enter ‘cool mode’ and

rotate the heat wheel to transfer heat from the outside air to the exhaust.

BASE

SETPOINT

The W‐TRAC is designed to be a discharge air temperature controller. The base discharge air temperature

is set from the setpoint control knob located on the face of the W‐TRAC.

SETPOINT

RESET

The base discharge air temperature is often modified from a remote signal to maintain the desired

temperature of the supplied space. This is called

reset

. The W‐TRAC discharge temperature can be reset

from a variety of sources using a 0‐10 VDC signal.

An offset to the BMS input range can be implemented by adding a 7.5k resistor in series with terminal S.

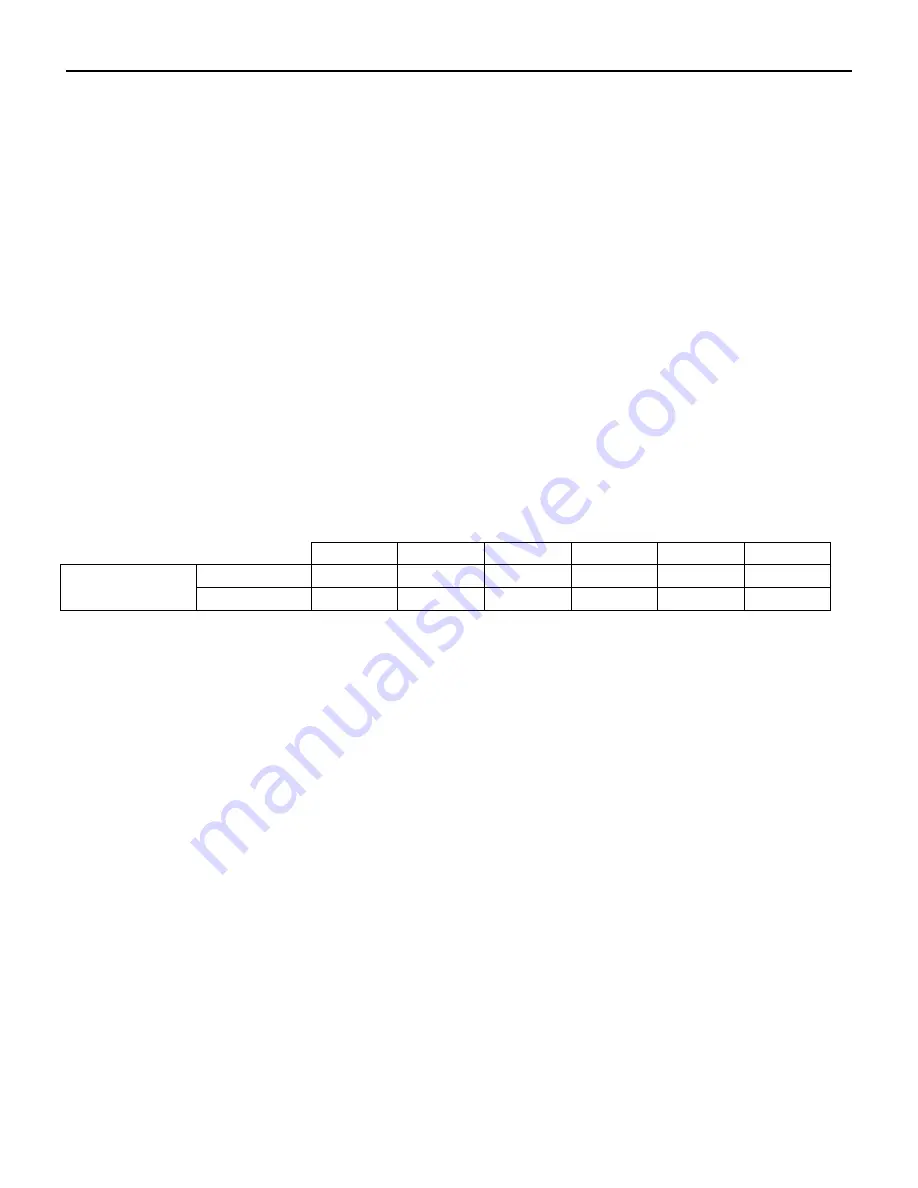

The following table describes the change of discharge setpoint from the input voltage (to terminals S + and

C1 ‐), with a setpoint fixed at 66°F. Refer to the equipment function page for the design reset range.

Input Voltage

0.0

2.0

4.0

6.0

8.0

10.0

Discharge

Setpoint (°F/°C)

No Resistor

30 / ‐1

40 / 4

45 / 7

52 / 11

60 / 15

66 / 19

7.5k Resistor

48 / 9

53 / 12

56 / 13

59 / 15

63 / 17

66 / 19

FROST

CONTROL

Frost should not be allowed to build up on the wheel. It is necessary to reduce the amount of heat

recovered when the outside temperature is below the freezing point (0°C / 32°F) and the exhaust leaving

temperature falls to a point that frost can begin to form. Frost may damage the wheel and reduce airflow.

Operating the heat wheel close to the frost threshold temperature will provide maximum energy recovery.

There are 3 different methods of providing frost control, all of which reduce the heat wheel rotation

speed.

EXHAUST

AIR

RH%

SENSOR

This method of control requires a humidity sensor connected across terminals EXH and C2. DIP 1 and 3

must be OFF, DIP 2 must be ON. The sensor is installed in the exhaust air section, just after the heat

wheel.