EK-Pak Owner and Installation Manual

EK-Pak Owner & Installation Manual First Edition December 2002

7

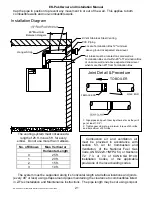

EK-Pak Technical Specifications

Natural Gas or Propane

Dimensions

28”H x 32”W x 10” Deep

Net Weight

110 lb. Package (60 lb. Heating Unit)

Input Rate BTU/hr

Min 20,000 – Max 185,000

Natural Gas

Min 19,000 – Max 175,000

LP/Propane

Electric supply

120 Volts, 60 Hz, 1.8 Amps max.

Energy Factor

84% Natural Gas

85% LP (Propane)

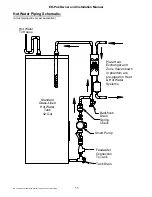

Closed Water Loop

Recirculated heating system water for maximum reliability

Sealed Combustion

4” flue

3” PVC or flex combustion air intake

Venting

Category III Positive Pressure, (Z-Vent)

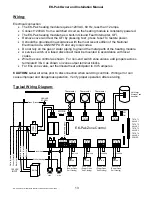

Versatile Heating Output

Baseboard Heat

60,000 BTU/hr

output (with 20% oversized radiation)

Hydro-Air Heat

120,000 BTU/hr

output

Domestic Hot Water

164 GPH

(80,000 BTU/hr output at 140F outlet water

temperature)

Radiant Heat &

Hot Tub

150,000 BTU/hr

(105F Maximum radiant temperature)

80,000 BTU/hr

(140F Maximum radiant temperature)

Pool Heating

150,000 BTU/hr

output

Heat Pump Backup

120,000 BTU/hr

output

Snow-Melt

150,000 BTU/hr

output

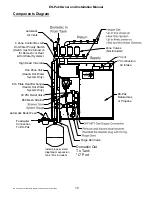

Theory of Operation

A very reliable, gas fired, modulating wall hung heating module is the source of heat for the

system. A fully featured closed loop hydronic heating system is integrated into the system.

The extremely versatile design is based upon research, development and field testing with

homeowners, professional installers and service people.

The EK-Pak system has been designed with a high head circulator to obtain maximum

water flow rate through the water heater. The advanced design uses a high pressure drop

through the heating module heat exchanger to achieve it’s efficiency and extraordinary speed

of response. Unlike conventional boilers, the high head circulator pumps into the heating

module heat exchanger, rather than pumping away from the heating module heat exchanger.

Due to the high pressure drop through the heat exchanger, the rest of the system, such as

baseboard, will remain at a reasonably low pressure.

A thermostat calls for heat and the zone control unit opens the appropriate zone valve and

starts the circulator. The heating module includes a flow switch that turns on the heating circuit

whenever flow through the heating module is detected. Once water begins to flow through the

zone, the heating module will turn on and begin to heat up the water flow to achieve the

desired supply temperature. Typically the supply temperature increases very quickly, so

quickly that a hand held on the supply pipe will have to be removed in about fifteen seconds.

Once the call for heat is satisfied, the zone control will close the zone valve and stop the

circulator.