EK-Pak Owner and Installation Manual

EK-Pak Owner & Installation Manual First Edition December 2002

19

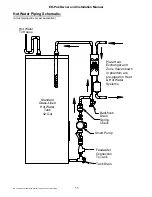

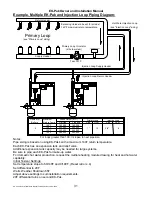

Flush, Purge, and Fill System with Water:

Follow these steps to flush, purge, and fill the system. Do not allow system pressure to exceed 30 psi.

♦

Flush

dirt, debris, and solder flux from system through the

strainer drain

.

o

Turn off power to the system.

o

Close purge ball valve.

o

Connect hose to

strainer drain

and open fully.

o

Manually open one zone valve.

o

Open heating module water feed. Water will begin to flow through open zone.

o

Open the next zone manually before closing the flushed zone valve.

o

Repeat until all zones have been flushed and then close the

strainer drain

.

♦

Purge

air from system through the

purge drain

.

o

Move drain hose to

purge drain

from the strainer drain.

o

Open purge drain and verify purge ball valve is closed.

o

Manually open one zone valve.

o

Open heating module water feed. Water will begin to flow through open zone.

o

Open the next zone manually before closing the purged zone valve.

o

Repeat until all zones have been purged.

o

Close

the

purge drain

and open the purge ball valve.

♦

Fill

the system through the heating module feed.

o

Adjust to normal cold system pressure, 10 to 12 psi on pressure gauge.

o

Add pressure if too low, relieve pressure if too high.

Once the system has been properly flushed and purged, the system will vent any released air

during operation.

NOTICE: AIR VENT CAP MUST REMAIN OPEN.

Vent cap should be removed and

kept in a safe location.

NOTICE:

DO NOT START BURNER UNTIL THE SYSTEM IS FULL OF

WATER.

Before placing system in operation, carefully check for leaks throughout system. Tighten

pipe joints, circulator flanges; check gaskets, etc., as needed.

Heating module Water Treatment:

Addition of heating module water treatment is recommended to reduce lime buildup inside

the heating module. Energy Kinetics recommends addition of one quart of 8-Way Boiler

Treatment per 30 gallons system water. 8-Way Boiler Treatment is recommended to treat

water up to medium hardness. Call Energy Kinetics for more details about heating module

water treatment and about hard water conditions.

Anti-Freeze:

Only non-toxic antifreeze (such as Propylene Glycol) should be used if adding anti-freeze

to a system that produces domestic hot water. Hard water should not be used in combination

with generic antifreeze. Energy Kinetics supplies a quality inhibited Propylene Glycol anti-

freeze with orange dye and an antifoam agent. 8-Way Boiler Treatment can be added to

Energy Kinetics anti-freeze and is recommended in areas of medium water hardness.

NOTICE:

Thoroughly clean system prior to adding antifreeze.

TSP is recommended for

removing flux and other oil based compounds. Once system has been cleaned and flushed,

then add antifreeze to obtain approximately a 30% by volume mixture of antifreeze in water.

Call Energy Kinetics for assistance in calculating how much anti-freeze to add to system.

Winterizing

The EK-Pak heating module comes equipped with heaters to discourage the unit from

freezing. For these heaters to work, there must be electrical power to the unit. This freeze

prevention system will not work if the electrical power source has been disconnected.