Fastlane

®

Pro Swim Unit Installation

Section 17

SCHEDULED MAINTENANCE

16.1 Hydraulic Motor and Fluid Maintenance. We recommend the hydraulic motor, which is located in your

swim unit and submerged underwater, be replaced after six years of usage. We also recommend chang-

ing the non-food grade, biodegradable vegetable oil and filter in the Power Unit after every 500 hours

of use.

16.2 Grill Cleaning. Should you perceive a reduction in speed of your Fastlane Pro, it may be caused by a

reduction in water flow due to a blockage of the inlet assembly of the cylindrical base. Because the un-

derside of your Fastlane Pro will be drawing in water, it may occasionally become necessary to clean

the cylindrical base of any debris or leaves that may have been in your pool when the Fastlane Pro was

in operation. With the Fastlane Pro unit turned off, this is very easy to accomplish while in the pool.

16.3 Cold Weather Maintenance. At the end of the swimming season, it is recommended the Fastlane Pro

Swim Unit be removed from the swimming pool and winterized. For specific instructions, please con-

tact our Customer Service Department at 800-910-2714 (US), or 610-497-4538 (Direct).

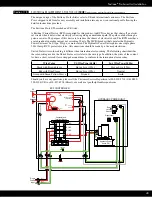

16.4 Use of Salt-chlorine generators. Placing a Fastlane Pro in a pool sanitized using a salt-chlorine gener-

ator creates increased risk of a hydraulic system failure and oil leaks. Any Fastlane Pro placed in this

type of environment must be properly bonded, and water chemistry must be closely monitored. As

stated in our warranty, pH levels must be maintained between 7.4 and 7.8, total alkalinity between 80

and 120 ppm, salt chlorine levels below 4000 ppm, and total dissolved solids below 7000 ppm. Failure

to properly bond the Fastlane Pro or maintain proper water chemistry will void the warranty.

If you are using a salt-chlorine generator, please complete the following tasks:

• Remove and inspect your Fastlane Pro unit annually. Once removed, rinse the Fastlane Pro with fresh

water before storing for the off-season.

• Replace the underwater hydraulic motor and submersible hoses every two years.

• Ensure that the fluid level in your power unit is no more than one cup above the float level switch.

This simple procedure ensures that any oil leak is minimized

16.5

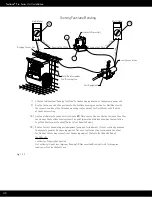

Cathodic Protection Maintenance Program. The Fastlane Pro has been fabricated using the finest,

most durable materials and has been designed to meet the most stringent safety standards, including

VGB 2008. However, unbalanced water chemistry and salt chlorine generators can shorten the lives

of these materials if the unit has not been properly bonded. Endless Pools has provided a sacrificial

anode to draw any corrosion to itself and away from the Fastlane Pro. To maximize the life span of

your Fastlane Pro, it is imperative that the Fastlane Pro be properly bonded and the sacrificial anode be

replaced after is has given up half its mass. Endless Pools offers a Preventative Maintenance Program.

This program will automatically send you a “sacrificial anode” on a regular basis for a nominal charge

to help prevent product damage due to electrolysis. Enrollment in this program is recommended if

the Fastlane Pro is installed in a pool with a salt-chorine generator. Contact Endless Pools Customer

Service at 800-910-2714 to enroll in this program.

47