-X

+X

+Z

-Z

+Z

-Z

-Y

+Y

Knee

Quill

Display shows: “BEEP ON” / “BEEP OFF”

Default: “BEEP ON”

Function:

This is used to disable the key beep if so required

Operation:

Press the key to toggle between “BEEP ON” and “BEEP OFF”

Display shows: “EXIT”

Default: “N/A

Function:

This is used to exit from Setup. Note any changes made will be saved

Operation:

Press the key to exit back to normal operation mode.

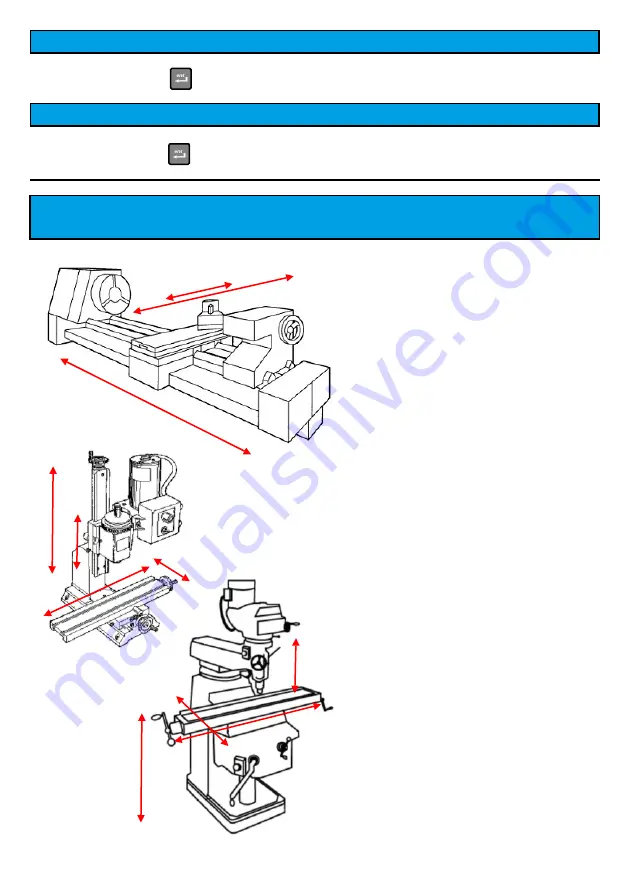

Machine Axis Conventions

-X

+X

-Z’

+Z’

-Z

+Z

On a lathe we have an X-axis (being the

cross-slide) and a Z-axis (the travel

between centres).

The top-slide can be rotated from

parallel to the X-axis to parallel with the

Z-axis through any angle. This is known

as the compound or Z’ axis. See axis

Summing later in this manual.

With milling machines we have the X, Y

and Z-axis. The X & Y-axis refer to the

table movement left-right and in-out.

The Z-axis can be either the Quill axis,

direct movement of the tool up-down

or the Knee axis which is the movement

of the whole table up-down.

On smaller machines the Z-axis can also

be the movement of the machining

head up-down independent of the tool

movement. As such it is quite possible

for a milling machine, of all sizes, to

have 4-axes of which two are vertical

movement.

-Y

+Y

+X

-X

-Z

-Z

+Z

+Z

Mini Mill

Knee Mill

- 7 -

Summary of Contents for EM250 Series

Page 2: ......