EMPYRE PRO SERIES INSTALLATION AND OPERATION MANUAL • 2009

7

SAFETY

WARNING

!

ELECTROCUTION HAZARD

ALWAYS SECURE DOOR WITH LATCH.

TIGHTEN WITH WRENCH.

815541

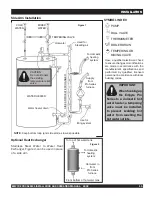

Electrical Ratings: 120 volts, 60HZ,

max breaker size 15 amps. (Blower

rating is less than 2 amps.)

For supply connections use No.14 AWG

or larger wires acceptable for at least

90ºC or equivalent.

For use with aluminum or copper

conductors.

815543

ELECTRICAL

INSTALLATION

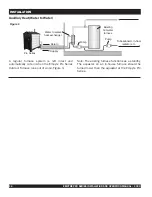

ADD ON INSTALLATION

INSTRUCTIONS

- This furnace can be connected to an

existing boiler system.

- Operate the (oil, gas, electric) boiler

periodically to ensure it will operate

satisfactorily when needed.

- DO NOT

relocate or bypass any of

the safety controls in the original

boiler installation.

CAUTION:

This equipment may only be

installed by qualifi ed personnel.

- Disconnect electric power to both

boilers before servicing.

CAUTION:

Maintain combustion air

supply to both boilers. Air starvation is

dangerous. Provide a fresh air opening

at least 2,000 mm

2

(3 in

2

).

An annual inspection by a qualifi ed

service technician is recommended.

INSTALLER INFORMATION:

Name__________________________

Address________________________

_______________________________

Date of Installation_______________

CAUTION

!

• THIS LID IS HEAVY.

• USE BOTH HANDS.

• LID AREA MAY BE VERY HOT.

• SWITCH BLOWER OFF BEFORE OPENING.

815544

DANGER

!

Risk of fi re or explosion.

DO NOT

start or fuel the fi re using

garbage, gasoline, drain oil or other fl ammable liquids or

chemicals.

WARNING

!

SAFE DOOR OPERATION:

- Stand

BEHIND

loading door and

SLOWLY

open. (Close

door if heavy smoke is present.)

WAIT

30 seconds

before opening door fully.

- Switch blower

OFF

for loading when fl ames are present.

- Always

CLOSE

and

LATCH

doors fi rmly. Switch blower

ON

.

-

DO NOT

operate with loading door and ash removal door open.

-

DO NOT

store combustible materials close to furnace.

- Follow listed combustibles installation clearances.

- Follow complete installation, operating and cleaning

instructions in Operator’s Manual.

CAUTION

!

-

Hot

surfaces do not touch.

-

KEEP CHILDREN

at safe distance.

-

DO NOT

damage furnace. Load wood carefully.

-

DO NOT

add fuel during a power outage.

-

KEEP

water level above the add mark.

- Place ash in metal containers and away from

combustible materials.

815545

SPECIFICATIONS

Install and use only in accordance

with the manufacturer’s installation/

operating instructions and local

codes. If there are no applicable local

codes, an outdoor installation chimney

must be listed to the ULC-S610 and

ULC-S604 standard and an indoor

installation must follow ANSI/NFPA

211 and NFPA90B. Chimney must

be a listed UL 103 HT or ULC S629

residential all-fuel type or tile-lined

masonry. Flue connector pipe must

be made of a minimum 24 NSG black

steel. Special precautions are required

for passing the chimney through a

combustible wall or ceiling. Refer

to authorities having jurisdiction for

proper installation.

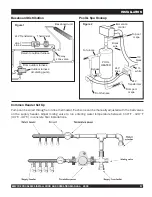

Minimum Clearance to Combustibles

Side Wall to Furnace

12” (305 mm)

Back Wall to Furnace 36” (914 mm)

Front of Furnace to

Combustibles

48” (1220 mm)

Combustibles to Flue 12” (305 mm)

Ceiling to Furnace

33” (838 mm)

CAUTION

!

-

DO NOT

connect the unit to a

chimney fl ue that serves another

appliance.

-

DO NOT

burn trash in this furnace.

-

DO NOT

pressurize water in

furnace.

-

DO NOT

dump ash close to any

combustible materials.

- The heat exchanger, fl ue pipe,

chimney must be in good condition

and cleaned regularly to remove

accumulated creosote and ash.

- Clean at the end of the heating

season to minimize corrosion

during summer months.

- Follow cleaning instructions in

Operator’s Manual.

- Refer to Operator’s Manual for

complete instructions.

In the event of loss of electrical power:

1. Open all check and zone valves in

the system. Depending on system

design, this may allow convective

circulation.

2. It is important to remember that

the heating system cannot dispose

of a great deal of heat without the

circulators running. Avoid over fi ring!

DO NOT LOAD LARGE AMOUNTS OF

SOLID FUEL INTO THE FURNACE!

Fire the furnace cautiously until you

are able to determine how quickly

the heat system is able to dissipate

the heat being produced by the

furnace.

3. When the power has returned,

reset all check and zone valves and

resume normal operation of the

system.

In the event of a runaway fi re:

1. Ensure the fi rebox door is tightly

closed.

2. Close all the combustion air inlets

on the furnace.

To cool an overheated furnace:

1. Turn all thermostats to their highest

temperature setting.

815546

1.

3.

4.

5.

6.

7.

1

6

2

3

5

7

4

EMPYRE PRO SERIES HYDRONIC FURNACE

15

Pro Series 100/200 #702112153 or #702111396, Pro Series 400 #70625938

Pro Series 100/200 #702112153 or #702111396, Pro Series 400 #70625938

Pro Series 100/200 no702112153 ou no 702111396, Pro Series 400 no 70625938

Pro Series 100/200 no702112153 ou no 702111396, Pro Series 400 no 70625938

815228

Model No./Certifi

én De Modèle

□

100

□

200

□

400 Serial No./ N° De Série ___________________________

Certifi ed H

eating Appliance CSA Standard B366-1-M91 UL Standard 391-2006/726-06 Standard C22.2 No. 3

Appareil De Chauffage Norme B366-1-M91 De La CSA Norme 391 De ULC - 2006/726-06 Norme C22.2 No 3

Appareil De Chauffage Norme B366-1-M91 De La CSA Norme 391 De ULC - 2006

Appareil De Chauffage Norme B366-1-M91 De La CSA Norme 391 De ULC - 2006

Certifi ed as an add-on model October 2007.

2.

Summary of Contents for Pro Series 100

Page 2: ......