22

EMPYRE PRO SERIES INSTALLATION AND OPERATION MANUAL • 2009

MAINTENANCE

During Heating Season

1. Establish a daily routine for storage of fuel and care

of the furnace. Check frequently for crusted ash

buildup until experience shows how often cleaning is

necessary. Be aware that the hotter the fire, the less

ash/tar is deposited in the firebox, and that weekly

cleanings may be necessary in mild weather, even

though monthly cleanings may be enough in the

coldest months. Have a clearly understood plan in

place in the event of a chimney fire.

2. The secondary burn chamber must be cleaned out

bi-weekly as necessary. Ensure that the ash clean out

door is securely closed after each cleaning.

Place ashes in a steel container with a tightly fitting

lid. Other waste should not be placed in the container

with the ashes.

3. Check the water level at least once a week, ensure the

level is well above the “ADD” mark.

Oxygen buildup causes corrosion inside the water

system. Keeping the water reservoir completely full

avoids oxygen buildup, especially during the summer

months when the furnace is not in use.

4. Check the door and lid gaskets to ensure an air tight

fit. Adjust hinges and latch as needed.

5. Check and clean the heat exchanger flues several

times per season. A buildup in the chimney and flues

will cause a poor draft and reduce efficiency (see pg

20).

6. Cover plates and guards must be in place at all times,

except during maintenance and servicing.

7.

Rear access door must be secure with latch locking

bolt. Tighten with a wrench.

8. Inspect brick as part of routine loading of the firebox

(see pg 19).

9. All doors must be closed during operation.

End of Heating Season

1. Thoroughly clean the firebox door frame, secondary burn

chamber, flue area, and flues of any loose or crusted

ash buildup. Crusted ashes are easier to remove when

furnace is still warm. Note: A thin black coating in the

firebox is acceptable, but ensure that there is no ash in

contact with bare metal.

2.

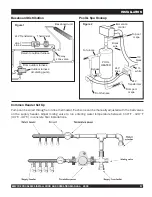

Check secondary air passage and clean if necessary.

To check, remove several of the bricks on the left side

of the firebox, including the last brick by the vertical air

tube found at the left rear corner of the firebox. The

air passage is now visible. Note the small air holes at

each of the brick slots. Ensure that air is free to flow to

each air hole. Also inspect the vertical air tube, if there

is creosote buildup, insert a small chain at the top of

the air tube, pull the chain through the bottom, pulling

it back and forth until the air tube is clean. Reinstall

the bricks in reverse order ensuring the back brick

is up against the rear of the firebox and against the

vertical air tube so that no air can escape. Place the

rest of the bricks tight against each other. If there is a

gap, it must be between the last inserted brick and the

front of the firebox.

Note:

The Pro Series 100 secondary air passage is on the

right hand side and has the vertical tube in the centre.

3. Check for damaged brick and replace as necessary.

Contact your dealer for replacement brick.

4. Check to ensure there is no moisture in any part of

the inside of the firebox, secondary burn chamber, or

flue area. Apply a thin film of oil in the flue area and

on the door frame and firebox where there is bare

metal surfaces that do not have a black tar coating.

5. Cover and seal the chimney to prevent any rain or

moisture from entering the heat exchanger area

while not in use.

Failing to properly clean the furnace and protect it

from moisture during the off-season will void the

warranty.

6. Ensure the water reservoir is full during the non-

heating season to prevent corrosion inside the water

jacket.

7.

Add the correct amount (as indicated on water

treatment bottle) of Pro-Fab approved water

treatment to the water system each year after the

heating season. Operate the water circulating pump

for 24 hours after adding water treatment to ensure

proper mixing of the water treatment with the water.

8. Draw a water sample once a year and forward to a

certified lab. Contact your dealer for details.

Water properly treated with Pro-Fab approved water

treatment should have a ph level between 9.1 and

10.7, a nitrate level between 730 and 1460 ppms

as NaNO2, and a conductivity must be less than or

equal to 4000 mmhos.

If the pH or nitrite level is low, more Pro-Fab approved

water treatment should be added. If the level of

conductivity is too high, 1/2 the water in the unit

should be drained and replaced with fresh water.

Failing to use Pro-Fab approved water treatment

in accordance with the Installation and Operation

Instruction Manual will void the warranty. See your

dealer for authorized supplies. It is the responsibility

of the owner to maintain yearly water sample results

on file.

Summary of Contents for Pro Series 100

Page 2: ......