12433-10-0109

Page 16

DVB-1 For Direct Vent Wall Furnaces DV-210-(7, 9)SG and DV-215-(7, 9)SG

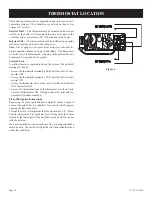

BLOWER

MOUNTING

TAB

Cleaning the Blower Wheel

In some areas, such as near bedrooms and on floors with a hard surface,

the blower wheel will be filled with lint very quickly. A visual check of

the blower wheel should be made after 30 days use. The blower will run

faster with a dirty wheel, but move less air. Remove the entire blower and

clean each blade of the wheel with a tooth brush as often as necessary.

Figure 1

INSTALLING OPTIONAL BLOWER DVB-1.

The blower must be posi-

tioned as shown in Figure 1. Relocate gas line, if necessary, using elbow

fitting at the gas valve, and move Piezo Spark Generator to the next screw.

A slot on the bottom of the blower package engages a tab on the bottom

of the inner casing and is secured by one screw in front.

Attaching Switch Box

1. Facing combustion chamber, remove (2) top, left screws on the com

-

bustion chamber door.

2. Align (2) clearance holes on the switch box (with fan control) over (2)

clearance holes on the combustion chamber door.

3. Insert and attach (2) screws removed in Step 1 into switch box and

combustion chamber door.

4. Attach switch box cover to switch box with (1) No. 8 x 1/4" screw.

Wiring

The appliance, when installed, must be electrically grounded in accordance

with local codes or, in the absence of local codes, with the National Elec-

trical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1, if

an external electrical source is utilized. This appliance is equipped with

a three-prong [grounding] plug for your protection against shock hazard

and should be plugged directly into a properly grounded three-prong re-

ceptacle. Do not cut or remove the grounding prong from this plug. For

an ungrounded receptacle, an adapter, which has two prongs and a wire

for grounding, can be purchased, plugged into the ungrounded receptacle

and its wire connected to the receptacle mounting screw. With this wire

completing the ground, the appliance cord plug can be plugged into the

adapter and be electrically grounded. A 7/8" (22mm) hole is provided in

the junction box for use with a conduit connector if local codes require

this type of protection.

CAUTION: Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

Oiling the Motor

Oiling holes are provided on each end of the motor for oiling. The blower

should have five drops of #20 motor oil every 6 months. Do not use

machine oil.

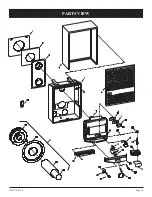

index no.

Part no. Description

1

R-1268

Wire Assembly

2

R-896

Bushing (Three Required)

3

R-1156

Fan Control

4

DV-806

Switch Box

5

DV-807

Switch Box Cover

6

TH-111

junction Box

7

R-1410

Bushing (Strain Relief)

8

R-285

Motor

9

R-587

Motor Cushion

10

TH-341

Blower Cushion

11

TH-356

Motor Support Assembly

12

R-319

Blower Wheel

13

TH-135

Blower Housing Assembly

14

R-315

Cord Set

oPtional BloWer installation instructions

Warning:

Unplugging of blower accessory will not stop the heater from cycling.

To shut heater off: 1. Turn the temperature dial to lowest setting, then

turn thermostat to off. 2. Turn knob on gas control to off, depressing

slightly. Do not force.