12433-10-0109

Page 6

introduction

Always consult your local Building Department regarding

regulations, codes or ordinances which apply to the installation of

a direct vent wall furnace.

Instructions to Installer

1. Installer must leave instruction manual with owner after

installation.

2. Installer must have owner fill out and mail warranty card supplied

with furnace.

3. Installer should show owner how to start and operate furnace

and thermostat.

Warning:

Any change to this furnace or its control can be dangerous. This

is a heating appliance and any panel, door or guard removed

for servicing an appliance must be replaced prior to operating

the appliance.

General information

This furnace is design certified in accordance with American National

Standard/CSA Standard Z21.86 and CSA 2.32 by the Canadian

Standards Association, as a Gravity Direct Vent Wall Furnace to be

installed on an outside wall according to these instructions.

Any alteration of the original design, installed other than as shown

in these instructions or use with a type of gas not shown on the

rating plate is the responsibility of the person and company making

the change.

important

All correspondence should refer to complete Model No., Serial

No. and type of gas.

Notice

: During initial firing of this unit, its paint will bake out and

smoke will occur. To prevent triggering of smoke alarms, ventilate

the room in which the unit is installed.

installation in residential Garages

Gas utilization equipment in residential garages shall be installed

so that all burners and burner ignition devices are located not less

than 18" (457mm) above the floor.

Such equipment shall be located, or protected, so it is not subject

to physical damage by a moving vehicle.

Qualified Installing Agency

Installation and replacement of gas piping, gas utilization equipment

or accessories and repair and servicing of equipment shall be

performed only by a qualified agency. The term "qualified agency"

means any individual, firm, corporation or company which either in

person or through a representative is engaged in and is responsible

for (a) the installation or replacement of gas piping or (b) the

connection, installation, repair or servicing of equipment, who is

experienced in such work, familiar with all precautions required

and has complied with all the requirements of the authority having

jurisdiction.

state of Massachusetts

: The installation must be made by

a licensed plumber or gas fitter in the Commonwealth of

Massachusetts.

The installation must conform with local codes or, in the absence of

local codes, with the

National Fuel Gas Code ANSI Z223.1/NFPA

54* Natural Gas and Propane Installation Code, CSA B149.1.

*Available from the American National Standards Institute, Inc., 11 West 42nd St.,

New York, N.Y. 10036.

High altitudes

For altitudes/elevations above 2,000 feet (610m) , input ratings

should be reduced at the rate of 4 percent for each 1,000 feet (305m)

above sea level. Canadian High Altitudes for locations having an

elevation above mean sea level between 2,000 feet (610m) and

4,500 feet (1370m), the manifold pressure is to be decreased from

4.0" w.c. (.996kPa) to 3.2" w.c. (.797kPa) for Natural Gas and from

10.0" w.c. (2.49kPa) to 8.0" w.c. (1.99kPa) for Propane Gas.

installation on rugs and tile

If this appliance is to be installed directly on carpeting, tile, or other

combustible material, other than wood flooring, the appliance shall

be installed on a metal or wood panel extending the full width and

depth of the appliance.

The base referred to above does not mean the fire-proof base as

used on wood stoves. The protection is primarily for rugs that may

be extremely thick and light-color tile that may discolor.

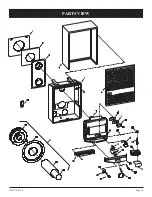

Model

DV-210

DV-215

Input BTU/HR (KW/H)

10,000 (2.9)

15,000 (4.4)

Height

21 3/8" (543mm)

24 7/8" (632mm)

Width

16 1/4 (413mm)

20 1/4" (514mm)

Depth

9 3/8" (239mm)

9 3/8" (239mm)

Gas Inlet

1/2" (13mm)

1/2" (13mm)

Options for Above Furnaces

Blower

DVB-1

DVB-1

Vinyl Siding Vent Kit

DV-822

DV-822

introDuction

sPeciFications