32186-0-0513

Page 10

sOME HELpFUL WARNINGs

• Use low heat output when children are nearby.

• Do not cover the floor register when the furnace or pilot is turned

on.

• Do not restrict the flow of air around the register by placing a

screen under it.

• Do not dry clothes or any objects by putting them on floor

register because this creates a fire hazard.

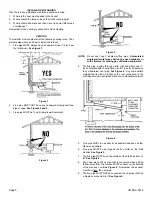

Figure 15

• Do not hang clothes or any object above or over floor register

because this too creates a fire hazard.

• During warm weather months, turn to full OFF position before

you cover the register with a rug, because this too creates a

fire hazard.

CAUtION

NEVER run your furnace with the lighter hole open or with a broken

lighter hole window. Exhaust gases can get into the living area

through an open lighter hole and be fatal.

pIEzO LIGHtING INstRUCtIONs

This unit is equipped with a Piezo (spark) for lighting the pilot without

removing the lighter hole cover. A lighter rod is supplied and can

be used to see if the pilot is getting gas and also for faster lighting

when there is excessive air in the lines.

REGIstER tEMpERAtURE CONtROLs

The register temperature control has two positions. LOW HEAT

(Black) output and FULL HEAT (Red) output. Use the low posi-

tion when children are present. This will cause your furnace to

turn off and on several times before the living area is completely

comfortable. This is normal and limits the register temperature to

a maximum of 235°F.

CAUtION

Contact of bare skin on the hot air register may result in burns when

the appliance is in operation. kEEP CHILDREN OFF!

You can reduce the heat of the register by moving the register

temperature control.

MILLIvOLt INFORMAtION

500 average with the thermostat OFF.

225 average with the thermostat ON.

140 minimum for valve to open.

65 minimum for pilot to stay on.

CAUtION:

Label all wires prior to disconnection when servic-

ing controls. Wiring errors can cause improper and dangerous

operation. Verify operation after servicing.

A. All units have been fire-tested to check the operation of the

furnace. This includes the BTU input, main burner flame, pilot

flame, limit controls and automatic operation. If problems

are encountered on initial installation the following should be

checked

1. Is the unit equipped for the gas being used?

2. Are all of the wires connected to the gas valve properly?

3. Is the venting system functioning? Check for spillage at the

diverter.

4. Is the gas inlet pressure proper? Read instructions for

minimum pressure.

B. It is necessary to use a millivolt meter to determine if the power

from the generator is adequate. 500 millivolts is normal with

the thermostat off and 140 millivolts minimum with thermostat

on.

C. This floor furnace cannot be expected to function properly if

exposed to wind as found when installed in a house supported

by pillars (open foundation). The wind is most harmful if it can

go beneath the front of the draft diverter and produce a pres-

sure directly on the outlet of the chamber. This wind can result

in pilot outage and a reduction in millivolts, causing the valve

not to open.

D. Good operation of the system is dependent on the pilot and

generator working properly. It is possible for the pilot to require

cleaning yearly. Replace pilot assembly if cleaning does not

produce proper flame. Replacement on generator alone is not

recommended.

E. Gas Valve will not open. To determine problem area:

1. By-pass thermostat on the wall.

2. By-pass thermostat at the valve.

3. By-pass limit and thermostat at the valve.

4. Check millivolts.

pROpER MAIN bURNER FLAME

ANd pILOt FLAME 3588

tROUbLEsHOOtING INFORMAtION

OpERAtING INFORMAtION