32186-0-0513

Page 12

Figure 16

The correct pilot flame will be blue and extend past the thermopile

as shown in the drawing. LP gas models do not require adjusting.

The input of Natural gas models will require adjusting if the inlet

pressure to the valve is above 5" w.c.

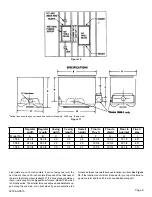

pROpER MAIN bURNER FLAME

5088, 7088

B

A

C

Figure 17

Inner Cone

Outer Cone Carry down flame

Model

Gas

(A) Dark blue (B) Light blue (C) Blue

7088

Nat

1 inch

2 1/2 inches 1/4 inch

LP

3/4 inch

2 inches

small cone

5088

Nat.

3/4 inch

2 inches

3/16 inch

LP

1/2 inch

1 1/2 inch

small cone

DO NOT MISTAkE AN ORANGE FLAME CAUSED BY PARTICLES

IN THE AIR FOR THE UNDESIRABLE YELLOW FLAME.

FLAME 360° AROUND

GENERATOR - COMING

TO TOP OF GENERATOR

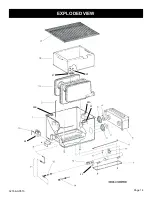

Figure 18

pROpER pILOt bURNER FLAME 5088, 7088

A blue flame shooting toward the main burner with an inner blue

cone and a larger light blue outer flame. The generator will be sur

-

rounded by a blue flame that terminates near the top of the generator.

HIGH ALtItUdEs

Orifice size must be reduced for high altitude use, or carbon monoxide

may be generated and excessive heat will seriously damage the unit.

When altitudes over 2,000 feet are specified, in the United States,

main burner spuds will be furnished to reduce input 4% for each

1,000 feet of altitude above sea level. Contact the manufacturer

or your gas company before changing spud sizes.

CHECkING MANIFOLd pREssURE

Both Propane and Natural gas valves have a built-in pressure

regulator in the gas valve with factory-set adjustment. Natural gas

models should have a manifold pressure of approximately 3.5"

w.c. at the valve outlet with the inlet pressure to the valve from a

minimum of 5.0" w.c. for the purpose of input of input adjustment to

a maximum of 7.0" w.c. Propane gas models will have a manifold

pressure approximately 10.0" w.c. at the valve outlet with the inlet

pressure to the valve from a minimum of 11.0" w.c. for the purpose

of input adjustment to a maximum of 13.0" w.c.

An 1/8" N.P.T. plugged tapping, accessible for test gage connection,

is located on the outlet side of the gas control.

CLEANING tHE MAIN bURNER

Remove the burner and apply air pressure inside the throat of the

burner and down into the ports.

Check for proper burner and pilot flame before and during each

heating season.

sERvICING

INstALLAtION ANd REpAIR sHOULd bE dONE bY A qUALI-

FIEd sERvICE pERsON.

The appliance should be inspected

before use and at least annually by a professional service person.

More frequent cleaning may be required due to excessive lint from

carpeting, bedding material, etc. It is imperative that control compart-

ments, burners and circulating air passageways of the appliance

be kept clean.

Floor furnace must not be connected to a chimney flue servicing

a separate solid-fuel burning appliance.

dON't

put anything around the furnace that will obstruct the

flow of combustion and ventilation air.

DO keep the appliance area clear and free from combustible

material, gasoline and other flammable vapors and liquids.

DO examine venting system periodically and replace damaged

parts.

DO examine burners periodically. Clean and replace damaged

parts.

MAkE

periodic visual check of pilot and burner flame.