B - 67

Vission 20/20 • Operation and Service Manual •Vilter/Emerson • 35391SC 2.0

Appendix B

•

Vission 20/20 Application Procedures

HARDWARE WIRING

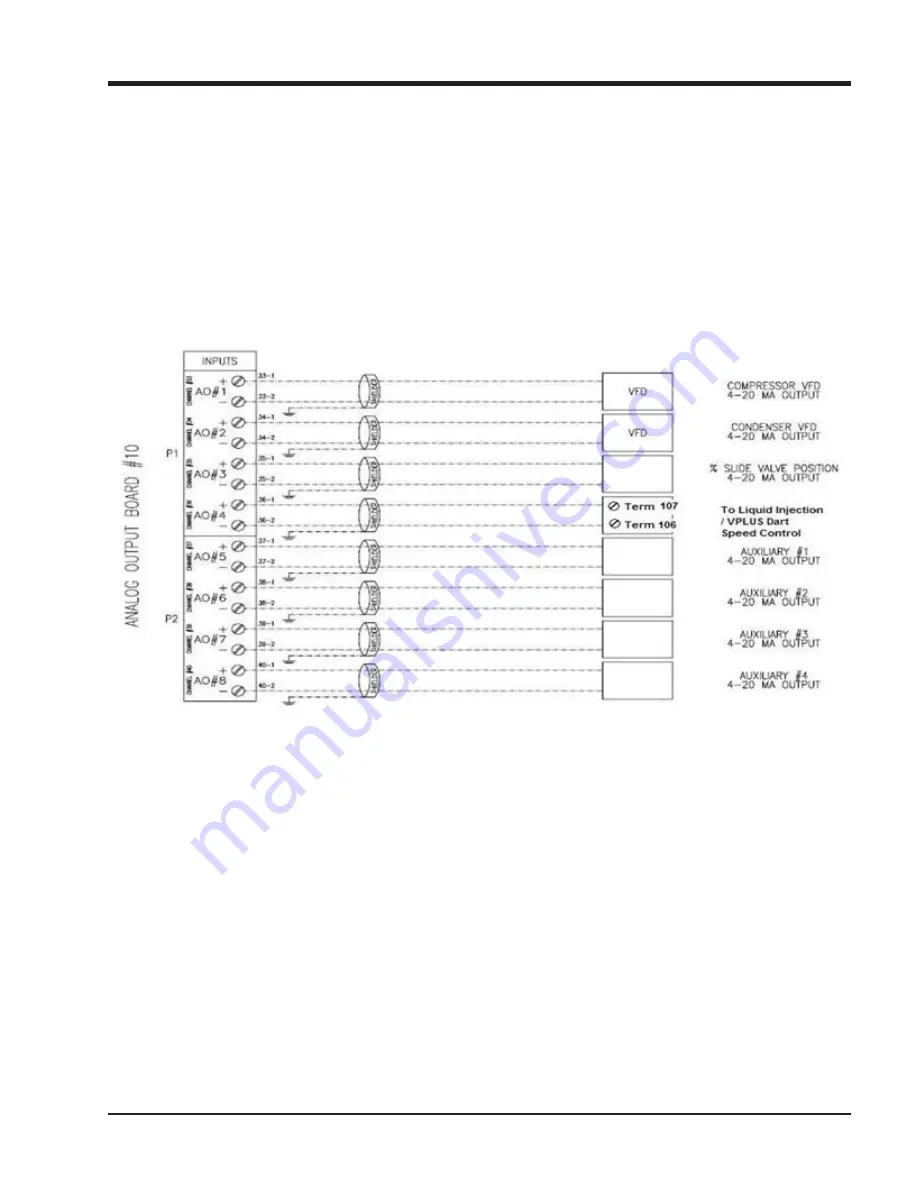

Interconnect wiring between the Vission 20/20 panel

and the VPLUS panel now needs to be done.

1. First make sure that the VPLUS panel and the

Vission 20/20 panel control power comes from the

same source.

2. Next, the Vission 20/20 analog output card must be

wired to the Dart speed controller board. The ana-

log output that is used for this is AO#4, see Figure

B-43. Wires from AO#4 will land on wires 106 and

107, see Figure B-42.

3. Finally, the VPLUS relay (CRV) shown in Figure B-42

must also be wired to the Vission 20/20. This relay

will be controlled by the Vission 20/20 digital out-

put (board #2, output #5) – the liquid injection so-

lenoid output. Run a wire from terminal 25 in the

20/20 panel to terminal 104 in the VPLUS panel, see

Figure B-43.

Figure B-43. Analog Output Card Wiring to VPLUS Dart Speed Controller (Wire 106 and 107)

Summary of Contents for Vission 20/20

Page 1: ...Vission 20 20 micro controller Operation and service manual Version 2 0 ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 66: ...8 4 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 76: ...10 8 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 86: ...12 6 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 106: ...15 4 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 1 9 ...

Page 108: ...16 2 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 136: ...21 4 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 146: ...24 4 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 154: ...26 4 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 156: ...A 2 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 158: ...B 2 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 162: ...B 6 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 180: ...B 24 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 204: ...B 48 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 220: ...B 64 Blank Vission 20 20 Operation and Service Manual Vilter Emerson 35391SC 2 0 ...

Page 257: ......