Operating instructions

Electrical Control Valves EX4-8

Emerson Climate Technologies GmbH

Date: 28.04.2020

Am Borsigturm 31 I 13507 Berlin I Germany

EX4-8_OI_EN_DE_FR_ES_IT_RU_R08_865288.docx

General information:

EX4-8 are stepper motor driven valves for precise

control of refrigerant mass flow in refrigeration, air

conditioning, heat pumps, industrial cooling process

and close control systems as:

-

expansion valves and liquid injection valves

-

suction pressure regulator (evaporator or crankcase)

-

hot gas bypass regulator

-

hot gas flow such as heat reclaim application

-

Condensing pressure regulator and liquid duty

Safety instructions:

•

Read operating instructions thoroughly. Failure to

comply can result in device failure, system damage

or personal injury.

•

According to EN 13313 it is intended for use by

persons having the appropriate knowledge and

skill.

•

Before opening any system make sure pressure in

system is brought to and remains at atmospheric

pressure.

•

Do not release any refrigerant into the

atmosphere!

•

Do not exceed the specified maximum ratings for

pressure, temperature, and voltage.

•

Do not operate system before all cable connections

are completed.

•

Do not operate valve connected directly to supply

voltage. Use suitable stepper motor driver.

•

Do not operate the valve when the compressor is

not running.

•

Do not operate the valve when system is under

vacuum except for closure of valve before

refrigerant charging.

•

Before installation or service disconnect all

voltages from system and device.

•

Do not use any other fluid media without prior

approval of EMERSON. Use of fluid not listed

could result in a change of hazard category of

product and consequently change of conformity

assessment requirement for product in accordance

with European pressure equipment directive

2014/68/EU.

•

Ensure that design, installation and operation are

according to European and national

standards/regulations.

Mounting location: (Fig. 1,2)

Expansion valve and liquid injection applications:

-

The motor needs to be pointed between downward to

sideways. (Fig. 1)

-

For best result, locate the valve as close as possible to

the distributor or inlet of evaporator.

-

Check for sufficient refrigerant charge/subcooling

and make sure no flash gas is present at the inlet of

valve before attempting to check valve operation.

Install an sight glass as well as a filter drier before the

valve.

Hot gas bypass applications:

-

The motor needs to be pointed downward.

-

Install the valves as far as possible from compressor

discharge.

-

It is also recommended to install a check valve (

)

on main hot gas pipe going to condenser after branch

line into the valve (

) (Fig. 2).

Suction line application:

-

The motor needs to be pointed downward.

Oil free system:

-

The motor needs to be pointed downward.

Installation:

•

Direction of refrigerant flow must match with arrow

on the label (except bi-flow valves).

Warning:

•

All valves are delivered at half open. Do not charge

system before closure of valve. See operating

instruction of used driver/controller.

•

The interior parts of valve must be protected

against moisture and water at any time. It is not

permitted the use of water, steam or any other

solvent to the inside of valve for cleaning purpose.

Brazing: (Fig.3)

•

Perform and consider the brazing joint as per

EN 14324.

•

Before and after brazing clean tubing and brazing

joints.

•

Minimize vibrations in the piping lines by appropriate

solutions.

•

Do not exceed the max. body temperature of

120°C!

•

Use flux and silver rod having a minimum of 30%

silver.

Pressure Test:

After completion of installation, a pressure test must be

carried out as follows:

-

according to EN 378 for systems which must

comply with European pressure equipment

directive 2014/68/EU.

-

to maximum working pressure of system for other

applications.

Warning:

•

Failure to do so could result in loss of refrigerant

and personal injury.

•

The pressure test must be conducted by skilled

persons with due respect regarding the danger

related to pressure.

Leakage Test:

Conduct a tightness test according to EN 378 with

appropriate equipment and method to identify leakages

of external joints. The allowable leakage rate must be

according system manufacturer’s specification.

Electrical Connection:

Warning:

•

Entire electrical connections have to comply with

local regulations.

•

Improper wiring will result wrong direction of

rotation or no rotation of stepper motor

•

Prewired plug (EXV-M…) are not in compliance with

EN60335-1-40/89 and are ready for connection to the

valve.

•

There is no specific requirement for positioning of

plug on pins (see Fig.5): Push the plug on pins on top

of the valve. Rotate the nut one turn in clockwise

direction and push the plug. Repeat this procedure

until the plug is tightened.

Wiring / Mounting to driver/Controller:

See the wiring diagram of applied driver/controller.

Operation:

•

See operating instructions of applied electronic

driver/controller.

Service / Maintenance:

•

Defective EX valves must be replaced, they cannot

be repaired.

•

For motor check:

-

Remove cable plug from valve.

-

Use an ohmmeter with suitable range.

-

Measure windings resistance per phase at opposite

placed pins acc. Fig.6 and data as in the table below.

•

EX4-8 has capability of positive shut-off when it is

driven to fully close position (as long as inlet pressure

is 0.5 bar above outlet pressure).

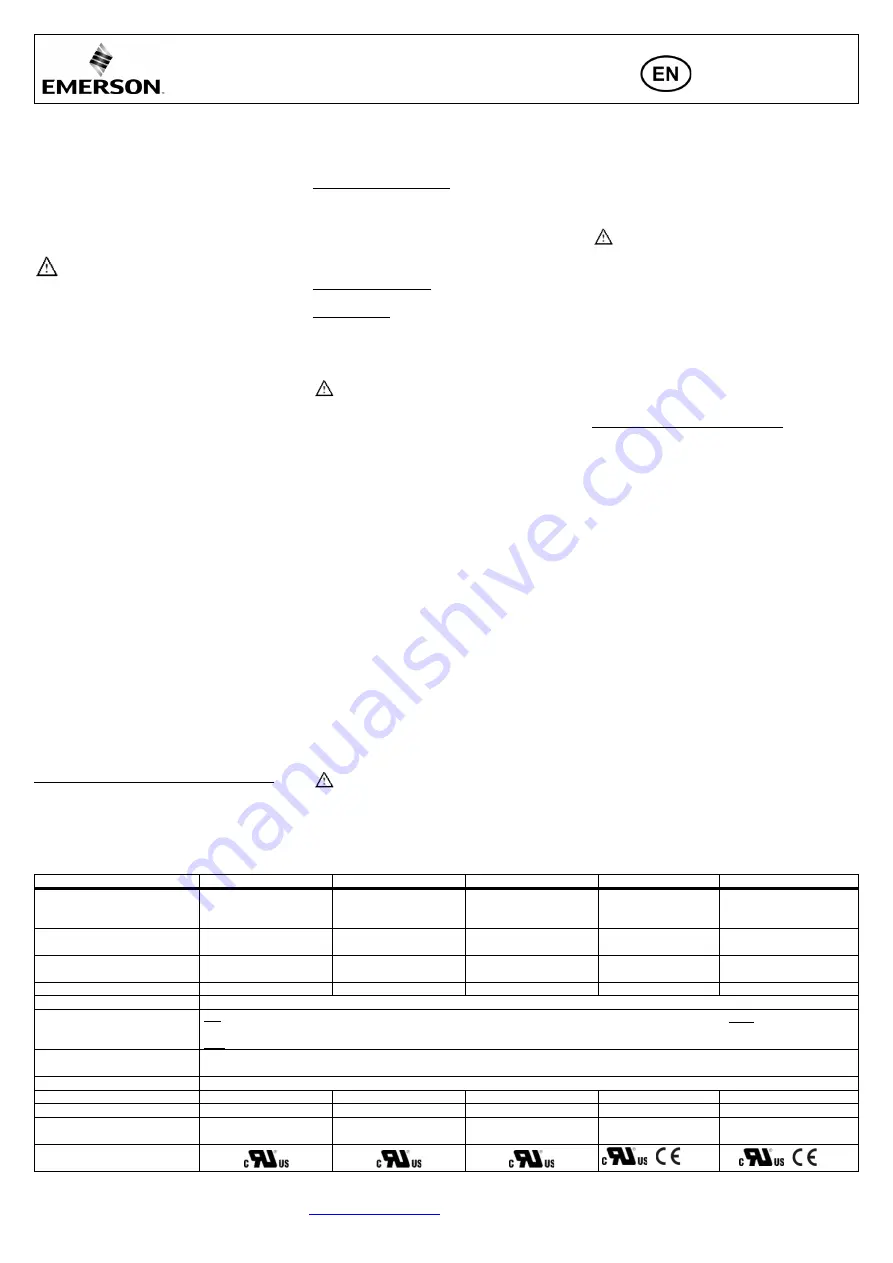

Technical Data:

Type

EX4

EX5

EX6

EX7

EX8

Maximum working pressure PS

90 bar (uni-flow),

60 bar (bi-flow)

UL Approval: all 60 bar

60 bar

60 bar

60 bar

45 bar

Factory pressure Test PT

99 bar (uni-flow),

66 bar (bi-flow)

66 bar

66 bar

86 bar

65 bar

Hazard category:

PED 2014/34/EU

-

-

-

II

II

PED Conformity Assessment

-

-

-

Module D1

Module D1

Fluid group (acc.PED)

I (listed A2L refrigerants) & II (listed A1 refrigerants)

Refrigerants

A1:

R744 (subcritical), R448A, R449A, R513A, R450A, R134a, R452A, R23, R410A, R407C,

R404A, R507, R124

Note:

UL Approval: only A1

refrigerants

A2L:

R1234ze, R32, R452B, R454B, R454A, R454C, R123yf

Operating temperature

at inlet:

Uni-flow: –50*… +100°C, Bi-flow: -50*…+80°C

at outlet:

-100*…+100°C

*) UL Approval:

≥

- 40°C

Dimensions

see Fig. 4

Nominal Supply Voltage U

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

Maximum Current Imax

0.5 A

0.5 A

0.5 A

0.75 A

0.8 A

Winding resistance per phase /

isolation resistance

14

Ω ±

10% /

> 20 M

Ω

14

Ω ±

10% /

> 20 M

Ω

14

Ω ±

10% /

> 20 M

Ω

10

Ω ±

10% /

> 20 M

Ω

7.5

Ω ±

10% /

> 20 M

Ω

Markings

,

1017

,

1017