24 • MultiFlex I/O Board Operator’s Guide

6.1.6. Input Screens

6.1.6.1.

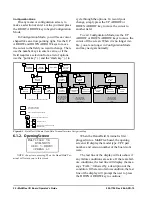

Input Status/Config Menu

The Input Status/Config Menu offers three

choices:

1.

STATUS-VOLTS -

Selecting this option will

show the status of all the inputs in volts.

2.

STATUS-ENG UN -

Selecting this option

will show the status of all the inputs in engi-

neering units. Engineering units must be

specified for each input using the Input Con-

fig screens (option 3), or else the board as-

sumes the input is a temperature sensor and

will display the input value in degrees Fahr-

enheit.

3.

INPUT CONFIG -

Selecting this option will

allow you to specify the engineering units for

each sensor connected to an input. Doing this

will allow you to see the sensor value in terms

of its intended engineering units.

6.1.6.2.

Status-Volts

The Status-Volts screen shows the current

input voltage of all inputs on the MultiFlex

board. Units with no inputs attached to them

(and with their input dip switches set to the UP

position) will read 5 volts.

The Hand-Held Terminal shows four inputs

at a time. To view more inputs, press the DOWN

ARROW key to scroll down.

6.1.6.3.

Status-Eng Units

The Status-Eng Units screen shows the same

information as the Status-Volts screen, except it

displays it in the engineering units designated

for that input (see

for more on

how to set the engineering units). The engineer-

ing unit chosen for the input is displayed in the

right-hand column.

The Hand-Held Terminal shows four inputs

at a time. To view more inputs, press the DOWN

ARROW key to scroll down.

6.1.6.4.

Input Config

The Input Config screen is where you spec-

ify the type of sensor that is attached to each

input and the engineering unit with you wish to

display the input values in the Hand-Held Termi-

nal.

Setting the engineering units using these

screens will only affect how their values are dis-

played in the STATUS-ENG UNITS screen

(

). Currently, neither Einstein

nor REFLECS is capable of reading the Multi-

Flex’s engineering units settings, so the sensor

type and engineering units will still have to be

specified in the controller in order for the inputs

to be read correctly.

Fields I01 through I16 correspond to points 1

through 16 on the MultiFlex board. To change

the engineering unit for an input, press the

RIGHT ARROW key to enter Configuration

Mode, and press DOWN ARROW until the cur-

sor points to the field you wish to change. Use

SELECT: 1

1= STATUS-VOLTS

2= STATUS-ENG UN

3= INPUT CONFIG

I01: 5.000 V

I02: 5.000 V

I03: 5.000 V

I04: 5.000 V

I01: 74.500 DF

I02: 111.200 PSI

I03: 75.200 DF

I04: 65.04 RH

I01: TEMP-DF

I02: 500 LB-PSI

I03: TEMP-DF

I04: HUMIDITY-RH

Summary of Contents for 810-3013

Page 1: ...026 1704 Rev 6 06 APR 10 MultiFlex I O Board Installation and Operation Manual ...

Page 2: ......

Page 4: ......