2-4-2

U25NDA

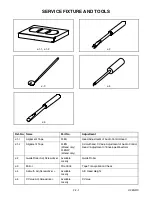

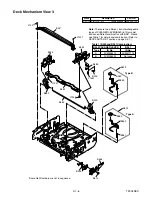

(1): Follow steps in sequence. When reassembling, follow the steps in reverse order.

These numbers are also used as ldentification (location) No. of parts in the figures.

(2): Indicates the part to start disassembling with in order to disassemble the part in column (1).

(3): Name of the part

(4): Location of the part: T=Top B=Bottom R=Right L=Left

(5): Figure Number

(6): Identification of parts to be removed, unhooked, unlocked, released, unplugged, unclamped, or desoldered.

P=Spring, W=Washer, C=Cut Washer, S=Screw, *=Unhook, Unlock, Release, Unplug, or Desolder

e.g., 2(L-2) = two Locking Tabs (L-2).

(7): Adjustment Information for Installation

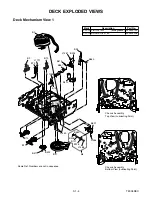

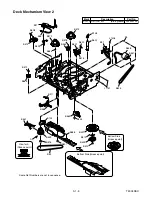

(+):Refer to Deck Exploded Views for lubrication.

.

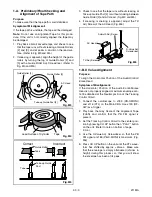

[33]

[2],[25]

M Brake T Assembly

T

DM1,DM16 *(P-6)

[34]

[2],[25]

M Brake S Assembly

T

DM1,DM16 *(P-7)

[35]

[34]

Tension Lever Sub

Assembly

T

DM1,DM16

[36]

[35]

T Lever Holder

T

DM1,DM16 *(L-6)

[37]

[33]

M Gear

T

DM1,DM16 (C-6)

[38]

[2],[15]

Sensor Gear

T

DM1,DM16 (C-7)

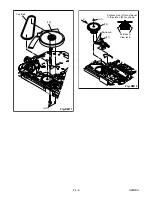

[39]

[33]

Reel T

T

DM1,DM16

[40]

[35]

Reel S

T

DM1,DM16

[41]

[31],[35]

Moving Guide S

Preparation

T

DM1,DM17

[42]

[32]

Moving Guide T

Preparation

T

DM1,DM17

[43]

[19]

TG Post Assembly

T

DM1,DM17 *(L-7)

[44]

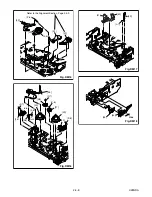

[19],[28] Rack Assembly

R

DM18

(+)Refer to Alignment

Sec.Pg.2-4-10

[45]

[44]

F Door Opener

R

DM18

[46]

[46]

Cleaner Lever Assembly

T

DM1,DM6

*(L-8)

↓

(1)

↓

(2)

↓

(3)

↓

(4)

↓

(5)

↓

(6)

↓

(7)

STEP

/LOC.

No.

START-

ING

No.

PART

REMOVAL

INSTALLATION

Fig. No.

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

ADJUSTMENT

CONDITION

Summary of Contents for 6319CC

Page 18: ...1 6 2 T7300DC Fig 1 ANT S 1 S 1 1 REAR CABINET S 1 S 1 S 1 S 1 Fig 2 ...

Page 20: ...1 6 4 T7300DC Fig 4 S 5 S 5 S 5 S 5 5 CRT CRT CBA ANODE CAP ...

Page 75: ...Packing X 1 S 1 S 4 S 3 S 3 S 2 TAPE TAPE X 4 X 3 X 2 X 7 S 6 S 14 FRONT 3 1 3 T7300PEX ...

Page 92: ...Printed in Japan 2002 02 20 HO SC319C 6319CC EWC1902 T7300UA 2UC 3UD ...