1-8-15

T5300TR1

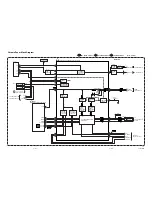

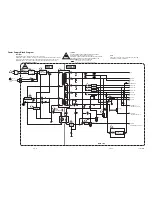

Check Fuse (F601) is blown

out or not.

If fuse is blown out,

do repair method #1

Check whether the primary

rectifying DC of the Switching

power supply has an output.

(Reading should be about 168V.

Voltage of the 105V line

higher than normal?

The transformer of the power

supply makes a higher sound

or the oscillation wave form is

abnormal.

(E.g. intermittent oscillation)

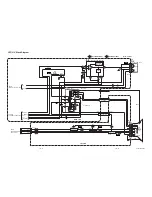

Connect the positive probe of

oscilloscope to the pin 16 of

T601, then connect the negative

probe to the pin 12. Observe the

waveform and check to see if

the waveform is out of limit of

value shown in Fig.1.

There is no problem on the

SW power supply

CHECK

#1

#2

#3

#4

Repair method

NO

NO

NO

YES

YES

YES

YES

NO

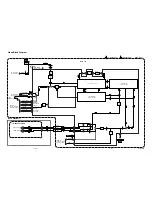

Power Supply Trouble Shooting Guide

It is highly recommended that a variable isolation

transformer which can monitor current be used.

(Alternatively a variable AC source which moni-

tors current will do). Read directions below before

power is added!

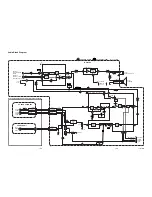

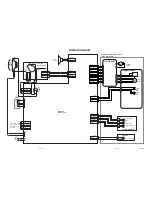

Repair method #1

(Power must be off)

Short circuit in the secondary side. check diode D613,

D614, D616, D617 and D618, switching transistor

(Q601), control transistor (Q602), diode and resistor

replace as necessary.

Disconnect 105V diode (D613), 25V diode (D614), 8V

diode (D616), 12V diode (D617), 12V diode (D618)

and Check the load continuity of 105V line, 25V line,

8V line, 12V line through a tester (resistance range).

If the tester indicates a lower resistance value around

0 ohm, the line is short-circuited.

Before repairing the switching power supply, find out

the short-circuited area of such line and repair it.

If the tester does not indicate any low resistance value

(around 0 ohm), no load is short-circuited and there is

no problem.

Check for any defective parts while the secondary rec-

tifying diodes are disconnected (D613, D614, D616,

D617 and D618) perform a diode check in both for-

ward and reverse directions through a tester.

Fig.1

0V

Voltage approx. 5Vp-p

T=Approx. 6 to 14 sec

Oscilloscope setting: 1V/DIV.

2 sec./DIV

Summary of Contents for 6319CC

Page 18: ...1 6 2 T7300DC Fig 1 ANT S 1 S 1 1 REAR CABINET S 1 S 1 S 1 S 1 Fig 2 ...

Page 20: ...1 6 4 T7300DC Fig 4 S 5 S 5 S 5 S 5 5 CRT CRT CBA ANODE CAP ...

Page 75: ...Packing X 1 S 1 S 4 S 3 S 3 S 2 TAPE TAPE X 4 X 3 X 2 X 7 S 6 S 14 FRONT 3 1 3 T7300PEX ...

Page 92: ...Printed in Japan 2002 02 20 HO SC319C 6319CC EWC1902 T7300UA 2UC 3UD ...