Using Your Gopher Getter

14

As you start and end a pass, smoothly raise, and lower the machine with the hydraulic cylinder to

minimize damage to the surface of the soil. In an emergency, the gopher getter can be quickly raised but

may disturb a significant amount of soil. To limit damage from erosion, avoid making burrows straight

down the slope of the hill.

This machine works best in moist soil. It is rarely a problem, but if the soil is too wet, it will stick to the

knife and the packer wheels and interfere with the depth setting of the gopher getter. A more common

problem is soil that is too dry. When it is, the machine will be very hard to get into the ground and it will

refill the tunnel (reducing the effectiveness of the bait). Depending on your soil type, you may find the

gopher getter works in a huge range of soil moisture conditions or that it works well in a narrow range of

conditions.

If you have certain types of soil or low soil moisture, the gopher getter may have trouble getting to full

depth (where the packer wheel will turn consistently). Typically, it works best when the torpedo tube is

sloping slightly downward into the soil (a few degrees). Try adjusting the angle of the frame by

changing the length of the lower arms on the three point. Next, reduce the depth of the coulter to reduce

the force required to get the machine into the ground. If this does not fix the problem, you may add

weight from 300 to 500 pounds, maximum.

The advice and tips above and below are generalized ones for gopher getter users throughout the

country. For information specific to your area, please speak with the dealer that you purchased the unit

from, your local extension agent, or area farmers that use gopher getters.

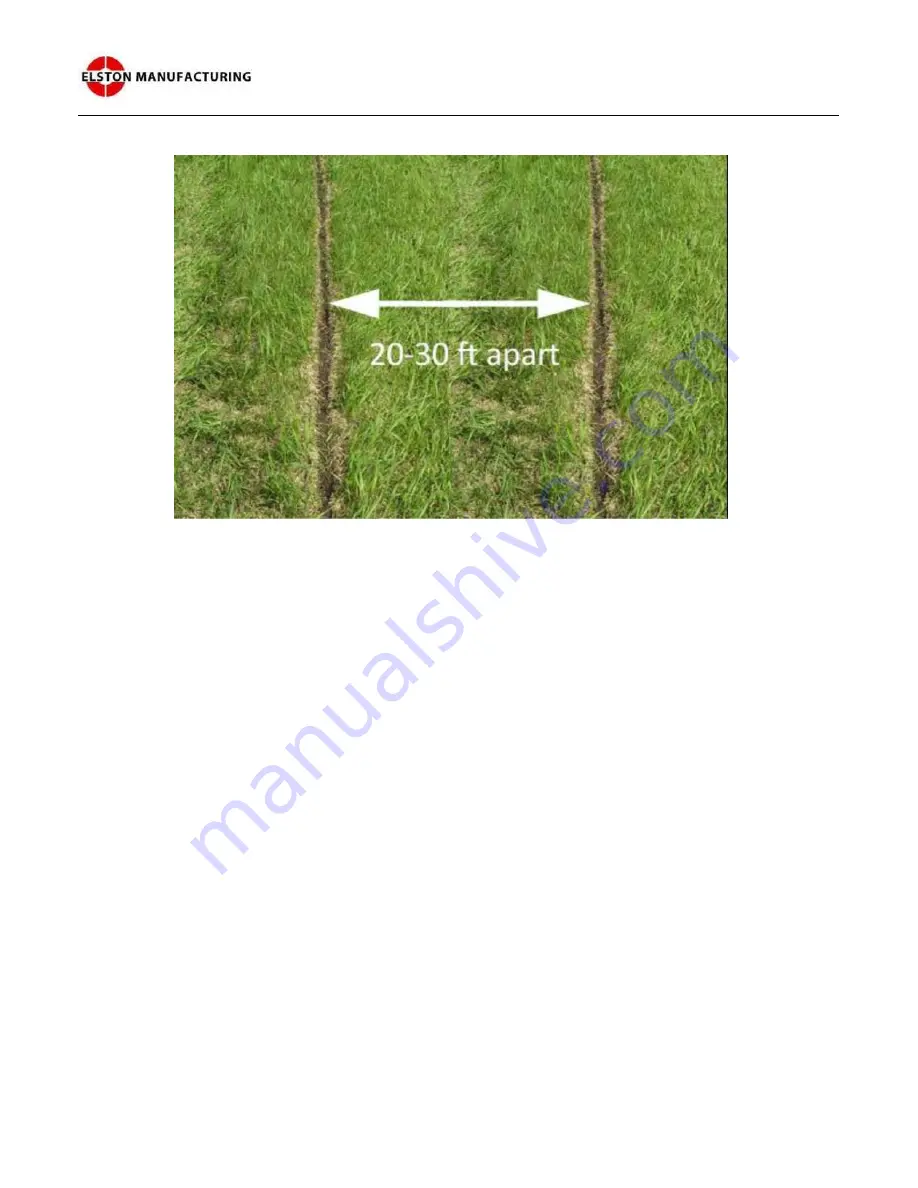

Figure 15: Application distance between application passes