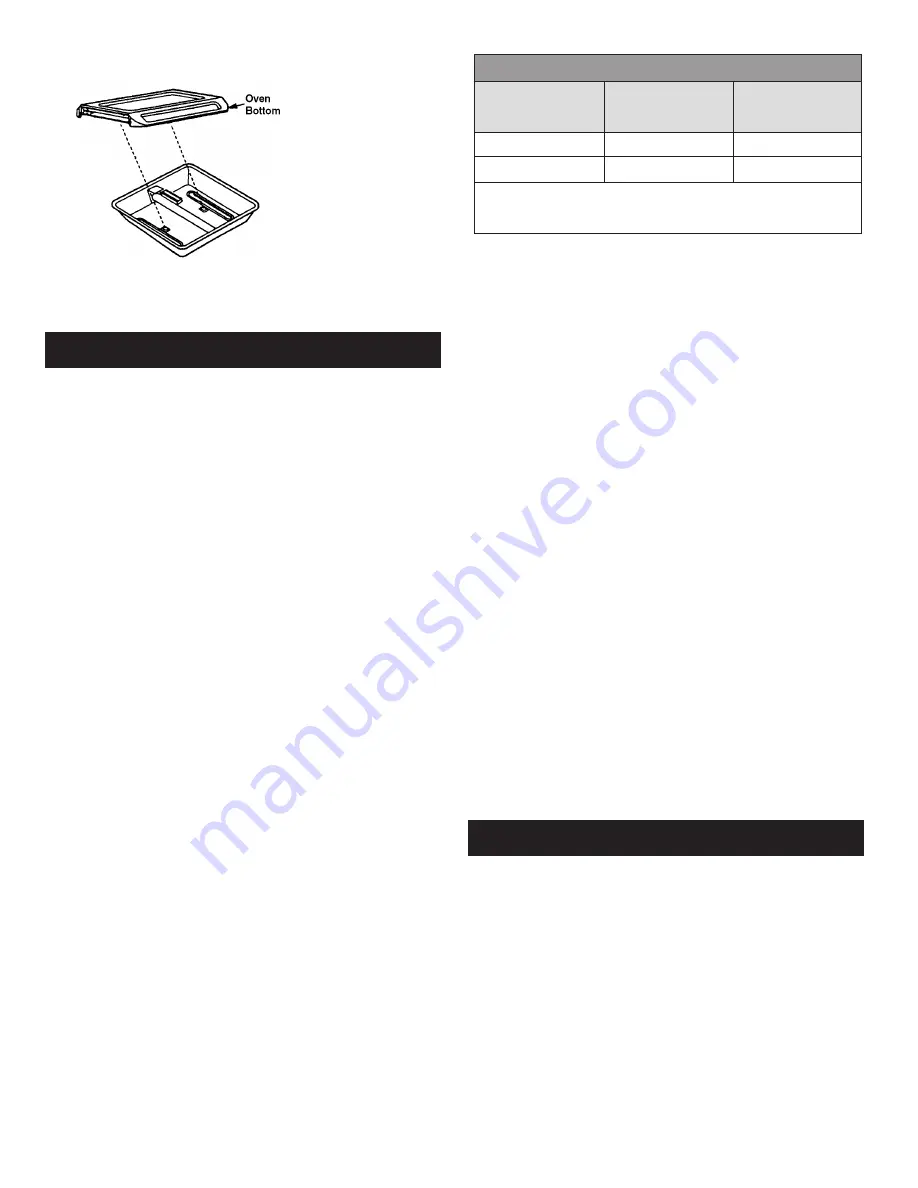

Hot air and moisture

escape from the oven

through a vent in the

center rear of the

cooktop.

Do not block

the vent.

Poor baking/

roasting and bad

combustion can result.

The oven bottom must

be in place for burner

to bake properly on

model 1956.

GAS SUPPLY SYSTEM

Gas and Electrical Supplies

Before connecting to the supply systems, be sure that

the installation conforms with the local codes or, in the

absence of local codes, with the National Fuel Code,

ANSI Z223.1 latest edition or in Canada, CAN/CGA B149

installation codes. See page

4 for electrical requirements.

Gas Piping to Range

The gas supply piping to the range should be 3/4” pipe

which is then reduced to 1/2” at the regulator. With

“LP” gas, the size of the piping to the range should be

determined by your gas fitter.

When connecting pipe to the die cast regulator fitting, use

two wrenches. Excess pressure or tightening the pipe too

tight can cause the regulator to crack, resulting in a gas

leak or a possible fire or explosion.

Make sure that if flexible connectors are used in

connecting the appliance to the gas supply, they are AGA

and/or CGA approved. Poorly designed connectors can

be a source of gas leaks. Even if AGA/CGA approved

flexible connectors are used, the customer should be

cautioned against kinking or damaging the connection

when moving or cleaning the range. This could cause a

gas leak.

Manual Shutoff

Install a manual shutoff valve in the gas line, in an

accessible location, near the unit. Know where the gas

valve is so you can shut off the gas to the range quickly.

Suitable pipe thread sealant must be used which is

approved for use with “LP”/Natural gas. Be sure to use

this thread sealant on all pipe connections.

Pressure Testing

The appliance, and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply system at

test pressures equal to or less than 1/2 psig (3.5kPa).

The gas supply pressure for checking the regulator

setting shall be at least one inch w.c. above

manufacturer’s specified manifold pressure.

Gas Leak Testing

After the final gas connection has been made, all the

top burner valves should be closed and the gas supply

and manual shutoff turned on. All connections in the

gas supply line and in the range should be tested with

soap suds or electronic sniffer for leaks. If a leak is

present, bubbles will appear. The leak should be stopped

by tightening the joint, or unscrewing completely and

applying additional pipe dope and re-tightened. Any

factory connections which may have been disturbed

should be retested.

A match should never be used when testing for leaks.

All fittings have been tightened and tested at the

factory. If a leak is detected, tighten the fitting. Don’t

use pipe dope on factory fittings.

FUEL CONVERSION OF RANGE TOP

Warning – Fire Hazard

• Locate gas supply shut off valve to the appliance.

• Shut off gas supply before converting fuels.

• Make all conversions before turning gas supply back on.

Failure to follow these instructions could result in fire,

explosion or other personal injury.

Models 1947, 1955 & 1956

All of our ranges are factory set to burn natural gas unless

“LP” is specified. If you are converting from Natural Gas

15

GAS-SUPPLY PRESSURE REQUIREMENTS*

Gas Type

Minimum Manifold

Pressure

Min. Gas-Supply

Pressure**

Natural Gas

Liquid Propane (LP)

5-in. Water Column

10-in. Water Column

6-in. Water Column

11-in. Water Column

*Gas-supply pressure for testing the regulator setting shall be at least 1 in. water

column (249 Pa) above the specified manifold pressure; **Max. gas-supply pressure

for all models: 1/2 psi.