0608

23

7

D1083

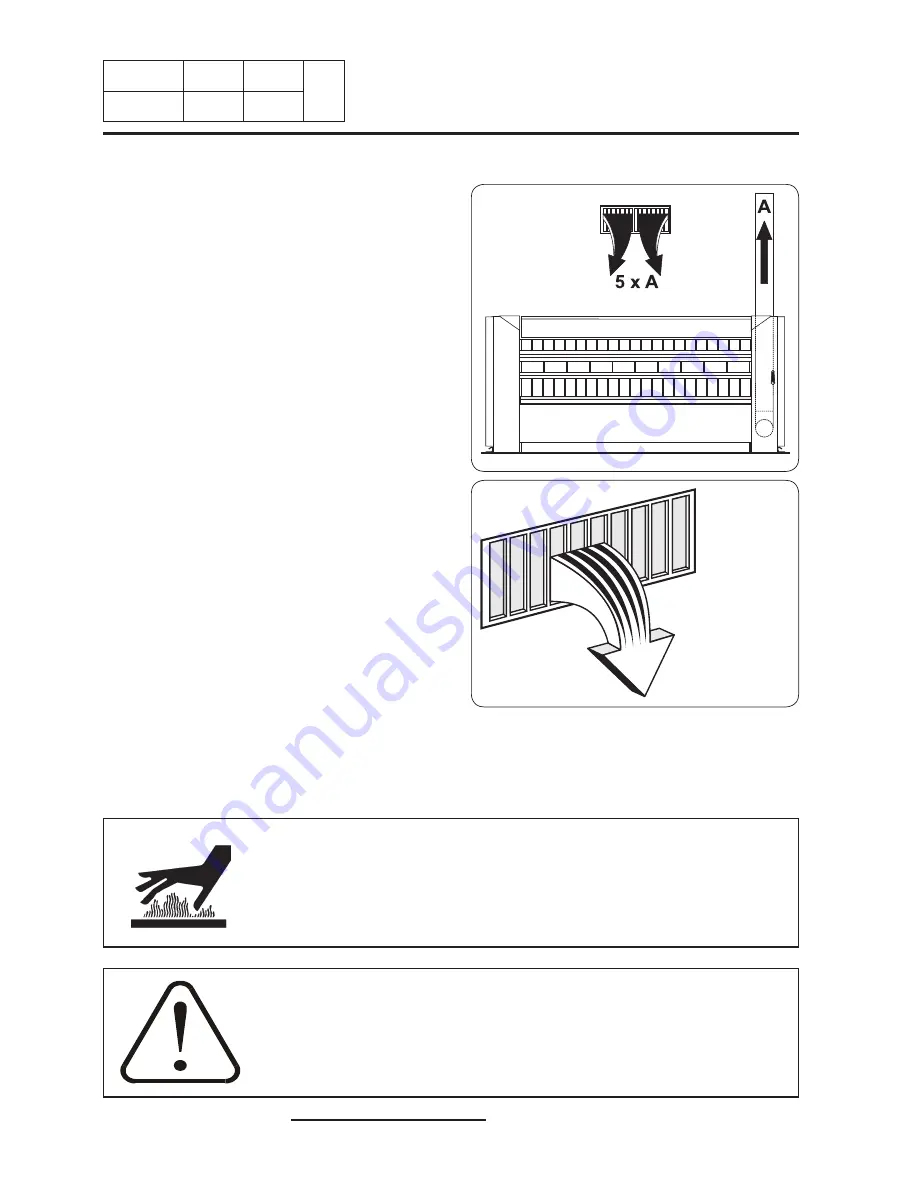

5 x A

D0460

Notice

Date Page

05102004

INSTALLATION

MANUAL

Connection of the ironer evacuation system

Fresh air inlet

To allow the dryer ironer to work at its best, it

is important that the laundry air inlet passes

through an opening from the outside.

The fresh air arrival must be equivalent to

the volume of evacuated air(please refer to

the output of the fans at zero pressure in the

technical characteristics).

Note :

In the case of several machines,

these values should be added together.

In order to prevent drafts in the room, the

best solution is to place the air inlet behind

the machine.

In the case of a machine with gas heating,

it is essential that the rooms should be

ventilated.

The free section of the air inlet must be

5 times greater than the section of the

evacuation pipe.

Do not forget to allow for the fact that grills

often occupy half the total area of the free

air opening.

Evacuation duct

It is recommended that a separate smooth-walled evacuation duct should be connected to each

dryer, providing the least possible resistance to air.

Check that the shaft flow is at least twice the capacity of the ironer exhaust fan.

It is essential that the diameter of the evacuation pipe should be

selected as a function of each installation so that the pressure

loss never exceed 200 Pa ( 0.029 psi) (value measured at ambient

temperature).

To prevent any risk of burnings, the vapours’ evacuation duct of the

flatwork ironers of the linen has to be temperature insulated (to be

done by the customer).

These conditions are

ABSOLUTELY ESSENTIAL

for correct working of the ironer.

7. Installation