Doc

#

E145703 V.1.14

QS - 4

Shark® 100 Meter Quickstart

Electro

Industries/GaugeTech

™

Powered by Innovation™

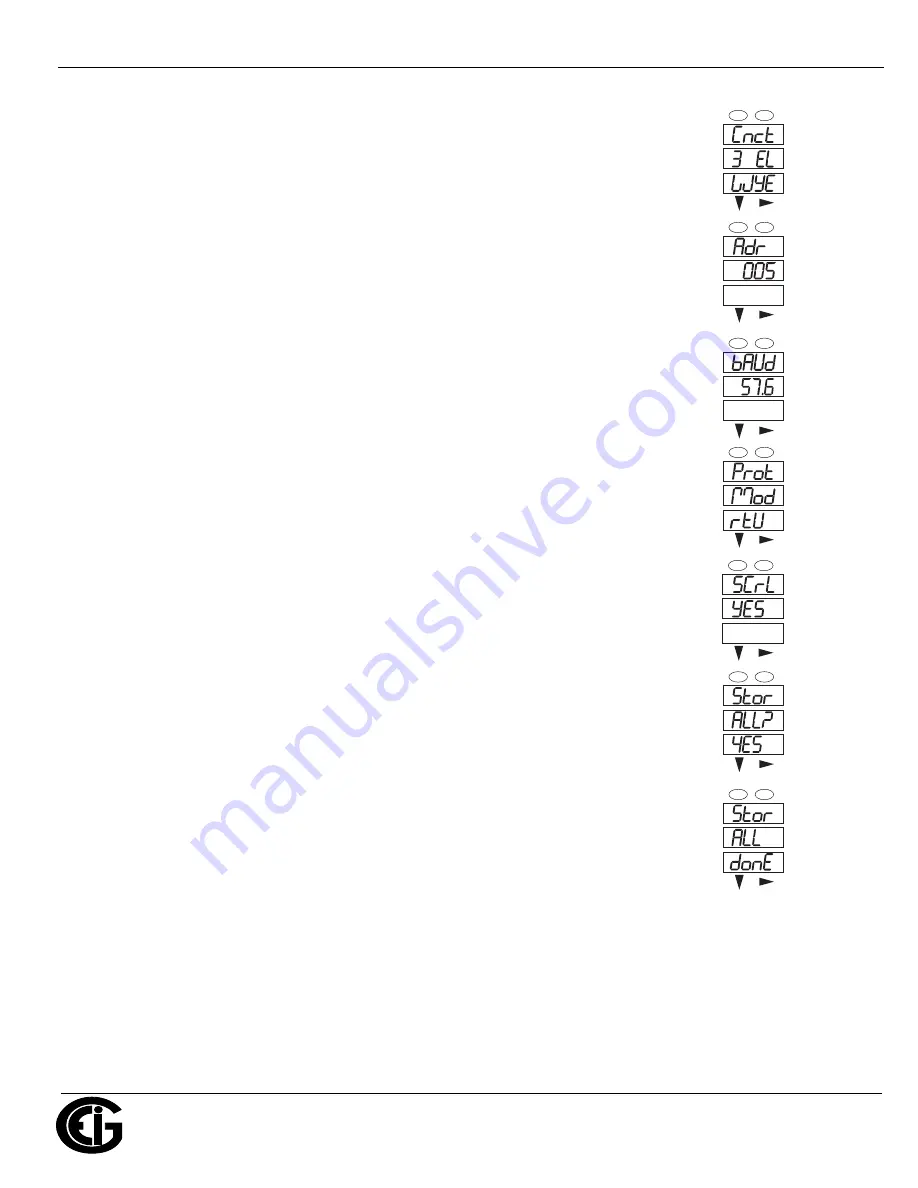

10.Press the

ENTER

button to go to the Connection setting screen (Cnct). The current

setting is shown in the second line. Press the

DOWN ARROW

to choose another

value. You can choose 3 EL (element) WYE, 2 Ct del (Delta), or 2.5 EL WYE.

11.Press the

ENTER

button to go to the meter Address setting screen (Adr). The

meter’s current address is shown in the second line. To change the setting, press

the

DOWN

ARROW

until the value you want is displayed. Then press the

RIGHT

ARROW

to move to the next digit. Repeat until the setting is done. Valid address-

es are from 001 through 247.

IMPORTANT! If you are using the Ethernet

option (INP10)

do not change any settings - leave the address as 001.**

12.Press the

ENTER

button to go to the meter Baud Rate setting screen (bAUd). The

meter’s current Baud Rate is shown in the second line. Press the

DOWN ARROW

to choose another Baud Rate. You can choose 9600 (choose this for RS485

connection), 19.2 (19200), 38.4 (38400) or 57.6 (57600).

IMPORTANT! If you

are using the Ethernet option,

do not change any settings - leave the Baud Rate

as 57.6.**

13.Press the

ENTER

button to go to the meter Protocol setting screen (Prot). The

meter’s current Protocol is shown in the second and third lines. Press the

DOWN

ARROW

to choose another communication Protocol. You can choose Mod rtU

(Modbus RTU; choose this for RS485 connection), Mod ASCI (Modbus ASCII),

or dnp (DNP 3.0).

IMPORTANT! If you are using the Ethernet option,

do not

change any settings - leave the protocol as Mod rtU.**

14.Press the

ENTER

button to go to the Scroll setting screen (SCrL). The current

setting is shown in the second line. Press the

DOWN ARROW

to choose another

setting. You can choose YES (the meter readings will scroll on the display) or no

(the meter readings will not scroll on the display).

15.Press the

MENU

button twice. You will see the Store Settings screen (Stor ALL?)

The default setting is YES. To save the settings you’ve made, press the

ENTER

button. You will see the confirmation screen (Stor ALL done) and then the meter

resets.

NOTE:

If you do not want to save your settings, press the

RIGHT ARROW.

YES

changes to no. Press the

ENTER

button.

**The Shark

®

100 meter’s Ethernet communication settings are the default settings of

Address 1, Baud Rate 57.6 and Protocol Mod rtU. See the

Shark® 100/100T Meter Installation and

Operation Manual

(see page QS-1 for the download link) for additional configuration instructions for

the Shark

®

100 meter’s Ethernet port

A

B

C

-

-

-

MENU

ENTER

A

B

C

-

-

-

MENU

ENTER

A

B

C

-

-

-

MENU

ENTER

A

B

C

-

-

-

MENU

ENTER

A

B

C

-

-

-

MENU

ENTER

A

B

C

-

-

-

MENU

ENTER

A

B

C

-

-

-

MENU

ENTER