This instruction sheet is not intended to be used in place of the Operator’s Manual. Use the following information

to assist you only after you have read, understood, and are accomplished in the procedures for cleaning and

sanitizing detailed in the Electro Freeze Operator’s Manual.

Cleaning & Sanitizing Flavor System Electro Freeze

®

Model CS705

SYRUP LINE CLEANING & SANITIZING

Important:

Do not use the “FREEZE” position with sanitizer or water in the

cylinder. The freezer will be damaged.

The syrup line system should be cleaned every 30 days. The

freezer should be fully cleaned prior to syrup line cleaning.

Records should be maintained to record last cleaning of

freezer and syrup lines.

Sanitizer noted in this section must be prepared according to

manufacturer’s instructions to yield 100ppm strength chlorine

solution ( Example: Stera-Sheen® Green Label) Use warm

water (100-110°F or 37- 43°C)

NOTE:

It is your responsibility to be aware of, and conform to, the

requirements for meeting local, state, and federal laws

concerning the frequency of cleaning and sanitizing the syrup

lines.

1.

Wash and sanitize your hands and forearms before cleaning

syrup lines.

2.

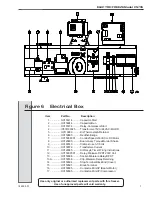

With syrup pickup tube in syrup bottle, disconnect syrup hose

from pump by pushing on metal clip of the connector. (see

figure 1). Slowly pull pickup tube out of syrup bottle allowing

syrup from the tube and hose to drain back into bottle. Place

stainless steel pickup tube in an empty bucket. Repeat for

each flavor and take hoses to sink and flush with hot water

(122°-140°F or 50°-60°C). Fill the bucket with hot water and

reconnect syrup hoses to the

pumps. Remove syrup bottles

from cabinet.

3.

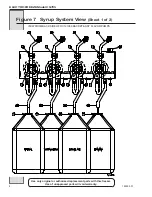

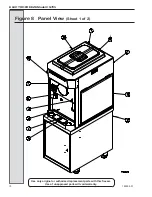

Place an empty container under

mix chamber. Turn syrup pump

switch to the “ON” position. Select

a syrup flavor by pushing proper

button (see figure 2) and then

press syrup prime/calibrate

button (see figure 3) to purge

syrup from line. Hold the button

and allow at least 1-1/2 cups of

hot water to flow through the tube and mix chamber.

Continue until water runs clear.

4.

Repeat step 3 with the remaining three syrup flavors.

Note:

At every cleaning or when a new syrup bottle is

opened, the cap with hole for syrup tube must be washed,

rinsed, and soaked in sanitizer for 5 minutes before

installing on bottle.

5.

With a container under mix chamber place selector

switch to clean and press rinse button for 5 seconds.

Spinner should be engaged splashing water in mixing

chamber.

6.

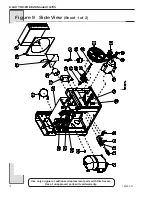

Disconnect each inlet line from pump. Separate

stainless tube from clear tube on each line and take to

sink to wash, rinse, and soak in sanitizer for 5 minutes.

Any separate container used for syrup storage must

also be washed, rinsed, and soaked in sanitizer for 5

minutes.

7.

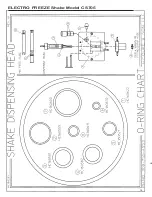

Disconnect each outlet hose from pump. Remove each

pump head from body by twisting 15° counterclockwise

and pull straight out. Remove hose assembly from

pump head and o-rings from connectors. Wash, rinse,

and soak in sanitizer for 5 minutes. Use 3/8” brush to

clean inside of tubes.

8.

Take a clean sanitized cloth and wash all soiled

surfaces inside cabinet. Disconnect syrup and water

lines from mix chamber. Remove mix chamber and

mixing shaft from dispense head. Take parts to sink,

remove o-ring and then wash, rinse and soak in

sanitizer for 5 minutes. Wash and spray sanitizer on

bottom of plunger in dispense head.

9.

Fill a small cup with sanitizer. Take mixing chamber and

dip syrup line quick connects into sanitizer for 30

seconds flushing residue out of connector. Use small

brush if necessary to remove hardened syrup. Repeat

dipping on outlet quick connect on syrup pump.

(over)

CLIP

CLIP

BANANA

CHOCOLATE

STRAWBERRY

SPECIAL

Figure 1 Removal of syrup lines to bottles

Figure 2

Figure 3