ELECTRO FREEZE Shake Model CS705

184592

38

Winter Storage

To protect the unit during seasonal shutdown, it is important to store the

CS700 Shake Freezer properly. Please use the following procedures:

1.

Disconnect all power to the freezer.

2.

Disassemble and wash all parts that come into contact with

the mix with a warm, mild detergent solution. Rinse in clear water and dry

all parts thoroughly.

3.

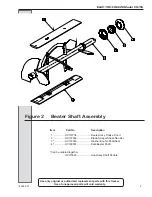

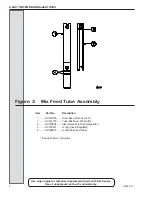

Store the loose parts, such as the head assembly, beater

assembly, and pump parts in a safe, dry place.

4.

Do not lay heavy objects on the plastic or rubber parts.

5.

Cover the freezer and all loose parts to protect them from dust

or other elements that could contaminate them while in storage. Place the

freezer in a dry location.

6.

On air-cooled freezers, have condenser fins cleaned.

12 Routine Maintenance

-— continued