HC184589, Rev 01 3/12

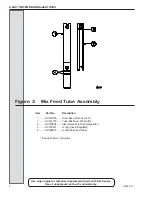

Look through top hole

in tube — you should

see clear through.

Look through top hole in

tube — you should see the

inner white plastic tube

(regulator) blocking the

opening.

ASSEMBLY

(con’t)

SANITIZING

1.

Wash and sanitize your hands and forearms.

2.

Prepare 2 gallons (7.6 liters) of sanitizing solution in a

container. The sanitizing solution must be mixed accord-

ing to manufacturer’s instructions to yield 100 PPM (parts

per million) available chlorine solution (i.e., Stera-Sheen

or equivalent).

3.

Place the mix feed tube assembly and mix float in the

bottom of the hopper pan. DO NOT INSTALL.

4.

Pour sanitizing solution into the hopper pan. Using a

clean brush, brush the hopper walls, mix level sensor, the

hopper drain opening from the hopper to the cylinder, the

inside of the mix feed tube, and the mix float.

5.

Install mix float on mix level sensor.

6.

When the cylinder has filled with sanitizing solution,

reconnect power, turn the selector switch to the “CLEAN”

position and allow the beater to run for 5 minutes. During

this time period, check for leaks around the head,

plunger, and drain tube.

Important:

Failure to completely remove sanitizer or water

from the freezing cylinder before placing in

“FREEZE” will damage the freezer.

7.

Place an empty container under the dispensing head.

Turn the selector switch “OFF” and drain the solution by

opening the plunger to allow the cylinder and hopper to

empty. Open and close the plunger approximately 10

times while draining to sanitize the port area of the

dispense head.

8.

Sanitizer can be used to sanitize product preparation

container.

Figure 3

Mix Feed Tube

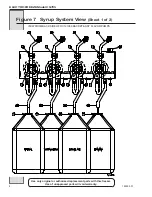

Figure 5

Pin is in line with hole.

Pin is not in line with hole.

1.

Wash and sanitize your hands and forearms.

2.

Install the mix feed tube assembly into the hopper

inlet port in the closed position as shown in figure 5.

3.

Fill the hopper with 2-1/2 gallons of mix.

4.

Place an empty container under the dispense head.

While holding the plunger open remove the mix feed

tube assembly from the hopper. Allow the mix to

force out all remaining sanitizer. When pure mix

flows from the dispense head close the plunger.

5

.

Allow the mix to flow into the cylinder until the

bubbling from the mix feed hole in the hopper stops.

Install the mix feed tube assembly in the hopper

pushing it all the way down. The regulator must be

in the “OPEN” position as shown in figure 5.

7.

Fill the hopper with mix and install the hopper cover.

Important:

Failure to completely remove sanitizer or water

from the freezing cylinder before placing in

“FREEZE” will damage the freezer.

8.

Turn the selector switch to “FREEZE” to begin the

freezing process.

9.

During long idle periods, the regulator should be

closed —

but remember — when dispensing

product, ensure that the mix feed regulator is

OPEN at all times.

If not open, the flow of mix will be

restricted. If lubricant blocks the inlet hole in the

tube it would also restrict the flow of mix.

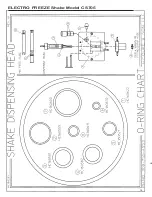

TUBE-MIX

FEED

INSERT-MIX

FEED

FLOAT

O-RING-

INSERT

(Lubricate)

O-RING

MIX FEED

PRIMING

Problem? Contact your local authorized distributor or

the freezer manufacturer, Electro Freeze Service Depart-

ment, 2116 Eighth Avenue, East Moline, IL 61244, (309)

755-4553, (800) 755-4545 or FAX (309) 755-9858.

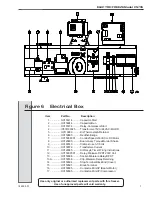

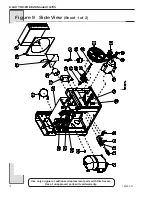

BLADE-

SCRAPER

SHAFT-

BEATER

(Lubricate)

WASHER-

SHAFT SEAL

SEAL-SHAFT

(Lubricate)

BUSHING

BEATER

BLADE-

SCRAPER

Figure 4 Beater Shaft