7.5M

7.5~

4

0M

1

2

3

6

5

4

1

2

3

4

5

6

1

2

3

4

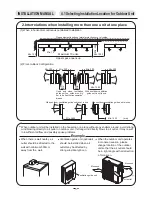

LO HI

INSTALLATION MANUAL

4.4 System Evacuating

Length of

Evacuation Method

Charging quantity

Connection Tube

of refrigerant

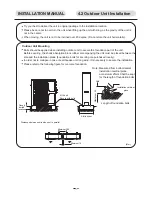

B. Evacuation using self-provide cooling

agent of the installing worker

1. Joint the self-provide refrigerant pot to the

nozzle of the low-pressure valve.

2. Slacken the high-pressure valve

copper

nut cap.

3. Open the refrigerant pot

so that the

refrigerant can come into the tube.

4. After 15 seconds, you may feel cold at

,

tighten

and close

. If the high-pressure

valve has nozzle, the operation will be easier,

just open the inner valve to evacuate the air

in the tube.

5. Take off the tube and evacuate the excessive

refrigerant through the inner core.

E v a c u a t i o n w i t h

self-provide refrigerant

of the installing worker

or by vacuum pump.

Nameplate

(55g of refrigerant for

each meter of added

pipe length.)

1. Refer to section of vacuum pump or using refrigerant

jar.

2. Quantity of charging refrigerant to be proceeded

as per above table.

When relocate air conditioner, evacuate with

vacuum pump or refrigerant jar.

Open valve rod to the suitable are, do not try to

open it more widely.

Tighten valve cap with wrench or similar tools.

Tighten torque on valve cap.

1. Joint multiple meter charging tube

to single-way

valve nozzle of low-pressure valve.

2. Connect charging tube joint with vacuum pump.

3. Open up multiple meter low-pressure valve (L0)

handle and tighten the high-pressure handle

completely.

4. Start vacuum pump for evacuation.

5. After completion of evacuation, completely close

multiple meter low-pressure valve (L0) hardle and

stop vacuum pump.

Make sure if multiple meter is at -10 X 10 Pa (-

76cmHg) after evacuation for over 15 minutes.

6. Remove charging tube from single-way valve nozzle

of low-pressure valve.

7. Tighten low-pressure valve cap.

Note: It is not recommended to evacuate using

refrigerant in the outdoor unit, which will

result in refrigerant insuffient. If conditions

not allow, it is necessary to use the refrigerant in the

system and charge more 80g-100g refrigerant.

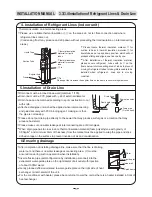

Attentions on Operation of Stop Valve

A. Evacuation with vacuum pump

5

1. Multiple meter

2. Multiple meter charging tube B

3. Multiple meter charging tube A

4. Single-way valve of the low-pressure

valve

1. Refrigerant pot

2. Refrigerant charging pipe

3. Low-pressure suction valve

4. High-pressure liquid valve

5. High-pressure liquid valve copper nut

6. Single-way valve of the low-pressure

valve

7. Connecting tube

The schematic diagram of suction valve

1. Connecting tube nut

2. Valve rod

3. Stopper (the set in the valve rod)

4. Valve cap

5. Single-way valve cap

6. Single-way valve rod (have valve core inside)

Evacuation using vacuum pump

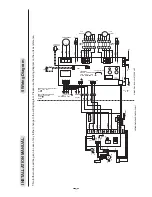

Summary of Contents for FS 1200

Page 4: ...FS KFR 120L OU10 50 R407C Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 9: ...Model FS KFR 120L Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 12: ...Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 13: ...FM FM 1 2 AUTO C AM Free Standing Air Conditioner Operation Instructions Installation Manual...

Page 53: ...Part No 452809000 01...

Page 54: ...Model FS KFR 120L Indoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 56: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 57: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 58: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...