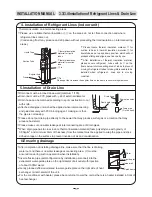

3.Installation of Refrigerant Lines (outdoor unit)

9.52

350~420

15.88

750~800

19.05

1000~1400

9.52

60 ~90

15.88 30 ~60

19.05 20 ~35

2.Operation on Tubing Connection

1) Remove 1 screw from handle of inlet grid, pull out to

your own direction and take inlet grid out. (As the

underside of inlet grid, is embedded in the bottom base,

please pull upward and take it out.)

2) Take down tap bolt (1) for securing pipe protection

cover, and remove pipe protection cover.

Pipe protection cover

inlet grid,

Bolt ... 1

Tap bolt 4X10 ... 1

After end of operation, it is necessary to install

according to original conditions.

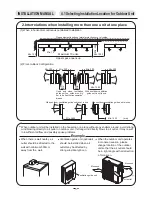

Tubing procedure:

1. Keep stop valve on outdoor unit in "off" status (ex-factory specification) as original, dismantle end caps

on refrigerant lines and the unit, and proceed quickly flare connection.

If being put aside for long period after end caps being removed, breakdown may happen to tubes

because of invasion of dust, water and foreign matter into pipe, so please proceed connection operation

rapidly.

Before tightening flare nuts, a layer of attached cooling engine oil should be thinly applied on the sealed

pad surface between tubes and connectors.

Please proceed tubing connections with two wrenches and refer to the following table for tightening

torque.

2. Proceed flare-connecting operation in succession and interconnect all refrigerant lines.

After pipes being connected, leakage detector or soup water must be used to check if there are any

leaks.

3. Proceed evacuation from service entrance of stop valve on the outdoor unit.

4. After completion of above operation, keep stop valve (commonly used by liquid and gas) on the outdoor

unit totally open. By then, refrigerant cycle between indoor and outdoor unit is all connected.

Attentions on application of flexible couplings

Please apply flexible couplings at indoor lateral interconnecting areas.

Bending angle cannot exceed 90 degree, and bending cannot be repeated more than 3 times.

To reach appropriate torque as per torque wrench

When without torque wrench,

please take following method as

standard: when tightening flare

nut with wrench, stop it and only

rotate to angle stated as right

table when tightening torque

increases quickly.

External dia. of

copper pipe(mm)

Torque (kg.cm)

Standard for torque angle

Note:

Please apply attached refrigerant lines thermal insulation materials

for insulation on indoor

lateral flare connection areas, and please make sure to proceed the operations stated as item

3 & 4.

Nonoxide brazing must be applied to pipes when proceeding brazing.

INSTALLATION MANUAL

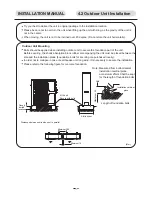

3.3/3.4Installation of Refrigerant Lines & Drain Line

Summary of Contents for FS 1200

Page 4: ...FS KFR 120L OU10 50 R407C Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 9: ...Model FS KFR 120L Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 12: ...Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 13: ...FM FM 1 2 AUTO C AM Free Standing Air Conditioner Operation Instructions Installation Manual...

Page 53: ...Part No 452809000 01...

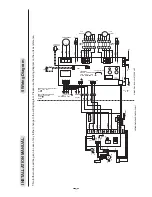

Page 54: ...Model FS KFR 120L Indoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 56: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 57: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 58: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...