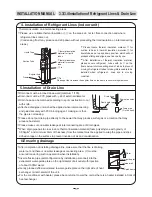

4. Installation of Refrigerant Lines (indoor unit)

Thermal insulation on interconnecting areas

Please use reliable thermal insulation

on the areas, do not let flare connection and where

refrigerant lines come out.

(Condensing frost may produce and drip down without proceeding thermal insulation on interconnecting

areas.)

Liquid Tube

thermal insulation

material for liquid

tubes

Suction Tube

thermal insulation

material for suction

tube

Tie

Frame

Angular hole

Tie

Please get the tie across the angular hole on the frame to secure

lines.

refrigerant

Please locate thermal insulation material

for

suction tube and thermal insulation material

for

liquid tube as per up and down position, which will not

produce sliding and align in one line one by one.

.

After installation of thermal insulation material,

please secure refrigerant

tubes with tie

on the

frame below interconnecting area of tubes to prevent

moving of refrigerant tubes. Intake grille is unable to be

installed when refrigerant

lines are in moving

condition

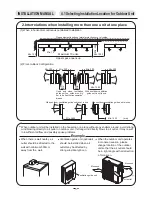

5.Installation of Drain Line

Drain line must be inclined downward (minimum 1/100).

Drain line must be PVC pipes with

26 of external diameter.

Drain hose can be matched according to spot construction to cut

with knife.

Attached drainpipe union shall be applied when interconnecting

and glued securely with PVC binding agent, making sure that

the pipe is not leaking.

Please do not put drain pipe directly to the sewer that may produce sulfur gas or a location that may

produce bad smell.

Please make sure no water leakage at interconnecting area of drain pipes.

When drain pipe has to cross indoor, thermal insulation material (foam polyethylene with gravity of

0.03kg/m and minimum 9mm of thickness) from the market must be applied to wrap the pipe and stick

adhesive tape on the surface to prevent invasion of air and condensation.

3

Drain hose

Drain pipe union

Plastic water pipe

Drain pipe

(On the spot)

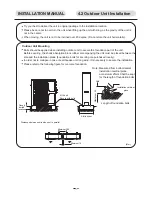

6.Ensuring drainage

After completion of installing drainage line, make sure that the line is draining

water out and there is no water leakage at connecting area. ( It must be

ensured too during suction operation when installation).

Insert effusion pipe (self-configuration by installation personnel) into the

evaporator water-guide plate on the right lateral of air outlet with injection

of about 1000ml water.

Gently proceed effusion oriented to water-guide plate on the right side of heat

exchanger or internal wall of the unit.

For the conditioner with heater, please be careful not to wet the unit as there is a heater installed in front of

heat exchanger.

Water

Water-guide plate

Internal wall

Catch basin

INSTALLATION MANUAL

3.3/3.4Installation of Refrigerant Lines & Drain Line

Summary of Contents for FS 1200

Page 4: ...FS KFR 120L OU10 50 R407C Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 9: ...Model FS KFR 120L Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 12: ...Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 13: ...FM FM 1 2 AUTO C AM Free Standing Air Conditioner Operation Instructions Installation Manual...

Page 53: ...Part No 452809000 01...

Page 54: ...Model FS KFR 120L Indoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

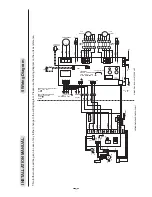

Page 56: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 57: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...

Page 58: ...Model FS KFR 120L Outdoor Unit Rev 01 Series FS Date 20 02 2004 ELECTRA CONSUMER PRODUCTS LTD...