Trispace AR Floor Standing Shell and TubeBoiler

21 L360

©

MHS Boilers 06/09/2013

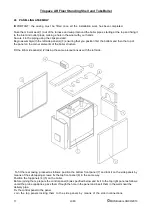

31 CLEANING OF THE BOILER

The boiler should be cleaned at least once a year to remove carbon deposits from the heat transfer

surfaces

Open the door, open the cleaning door and take the turbolators out (you need to disassemble the upper part

of the real panel).

Clean the smoke pipes using a steel brush and remove the soot from and the rear cleaning door.

32 CHECKS AFTER THE BOILER CLEANING

After performing the maintenance and cleaning operations, repeat the preliminary operations prior

to switching on for the first time (see page 22),

check the burner setting and perform combustion analysis.

Check the fuel supply system seal: this check is particularly important when

using gaseous fuels.

Check that the combustion circuit is perfectly sealed and replace any worn gaskets.

Check the system hydraulic seal to avoid unnecessary exchange of water and topping up which will increase

the risk of scaling.

Should the boiler water ways be scaled, a chemical washing is needed to remove scale.

This operation must be performed by qualified companies.

The specifications of the plant water should be examined and, if needed, a treatment system should be

installed.

Never leave highly inflammable substance containers in the premises where the boiler has been installed.

33 TROUBLESHOOTING

Below is the description of the most common faults and their remedy:

FAULT: the burner does not turn on.

REMEDY:

- check electric connections;

- check the regular fuel supply;

- check the integrity and the cleanness of the fuel supply system and that no air is present;

- check that ignition sparks form regularly and the burner appliance works correctly;

- check the boiler safety thermostat operates correctly;