Trispace AR Floor Standing Shell and TubeBoiler

7 L360

©

MHS Boilers 06/09/2013

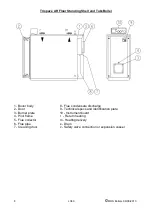

This is a pressurised combustion three-gas pass boiler:

the flame produced by the burner develops in the furnace (1

st

passage); the opening at the end of the

furnace leads to a duct through which products of combustion are conveyed until they reach the front

area (2

nd

passage).

Combustion gas inversion is clearly separated from the furnace in order to

reduce NOx. Products of combustion remain in the high temperature area causes low NOx formation.

In the front area, through the groove in the manhole insulation, products of combustion are

conveyed to the tube collection (3

rd

passage)

Here the products of combustion are forced by special turbolators to follow a whirling path which

increases the heat transfer due to convection. Maximum heat absorption is therefore obtained without

noxious gas or thermal stresses and above all with over 93% increase in the working efficiency.

On leaving the dry pipes, the products of combustion are collected in the rear chamber and conveyed to

the flue.

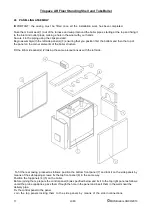

Burners fired with traditional liquid and gaseous fuels can be installed. The burner is installed on a hinged

door; this facilitates regulation and maintenance of the boiler and the burner without having to take out the

latter

The thermal insulation of the boiler body is obtained by applying a pad of highly insulating mineral

wool to keep thermal dispersions at very low levels. Elegant pre-painted steel panels complete the outside

finish.

As a result, there are many advantages with TRISPACE AR series: there is less fuel consumption, greater

heat exchange efficiency.

The pre-connected electric control panel that automatically controls the boiler is positioned on the top of the

boiler.

The electric diagram can be found inside the control board and in Appendix 1.